Colten Edwards

Fabricator

so in the shop I've been busy like a canadian beaver on CNC projects. Last summer I purchased a 50w CO2 laser from a company in Toronto off of ebay. Not the greatest laser in the world, but it works. One thing I wanted todo with it were mugs etc so I had to build a rotary axis. The design I found on openbuilds.com

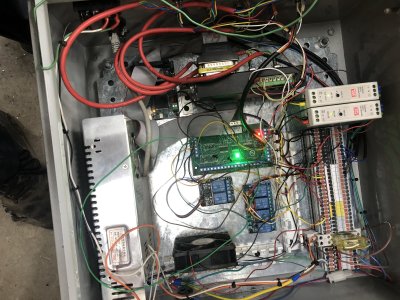

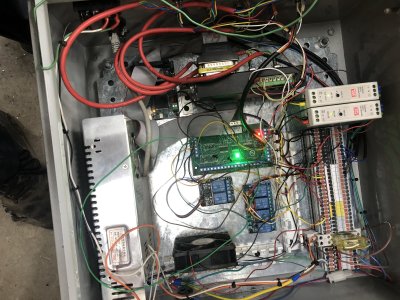

After this I finally finished and got my plasma table working. Still need to leak test the water table, but the machine is functional.

In the meantime, friend of mine had purchased a diode laser which we junked the frame of, and created a new one based on the ortur laser master. Of course I had to try one as well, so I purchased a laser diode from bangbad and created a diode laser running grbl controller and lightburn. Also upgraded the CO2 laser to a smoothieware based board so I could use lightburn with it. Christmas I made a two hundred or so ornaments which paid for the laser and the upgrades. While watching youtube video's I came across a video series on building your own laser, so off to aliexpress to order $2k in parts including a new 50w tube and power supply. Cutting size on this laser will be 4ftx2ft with adjustable Z bed. I'll be using a Duet3 board for motor and gcode since I took my large 3d printer apart to make a diode laser If anyone's interested, lookup Further Fabrication on youtube. He sells the build guide which is really nicely put together for $5 and the stl's for another $5. Definitely worth the money. Laser I'm building is called a Y1200 and he has a smaller version called the Y400. There's also a facebook group.

If anyone's interested, lookup Further Fabrication on youtube. He sells the build guide which is really nicely put together for $5 and the stl's for another $5. Definitely worth the money. Laser I'm building is called a Y1200 and he has a smaller version called the Y400. There's also a facebook group.

Next on the agenda my friend want's a small cnc router, so off to the internet and after some hunting around we found a site called makerCarver which had the DXF's for all the plates to create a cnc router. I modified them a little since we wanted to use mgn12 linear raikl on the X and Y axis. After many prototype's in plywood, I finally had a set of plates which would work for linear rail's as well as keeping some of the rigidity of the wheels. I cut the plates from 1/4" acrylic and one of the first projects for this router will be to create the plates from 1/4" aluminum. Once that's done, I'll convert my diode laser into a small format router with laser attachment in a larger size since I'm not too cheap to order proper rails

So there's my update on what's happening in the edwards shop in these covid times.

After this I finally finished and got my plasma table working. Still need to leak test the water table, but the machine is functional.

In the meantime, friend of mine had purchased a diode laser which we junked the frame of, and created a new one based on the ortur laser master. Of course I had to try one as well, so I purchased a laser diode from bangbad and created a diode laser running grbl controller and lightburn. Also upgraded the CO2 laser to a smoothieware based board so I could use lightburn with it. Christmas I made a two hundred or so ornaments which paid for the laser and the upgrades. While watching youtube video's I came across a video series on building your own laser, so off to aliexpress to order $2k in parts including a new 50w tube and power supply. Cutting size on this laser will be 4ftx2ft with adjustable Z bed. I'll be using a Duet3 board for motor and gcode since I took my large 3d printer apart to make a diode laser

Next on the agenda my friend want's a small cnc router, so off to the internet and after some hunting around we found a site called makerCarver which had the DXF's for all the plates to create a cnc router. I modified them a little since we wanted to use mgn12 linear raikl on the X and Y axis. After many prototype's in plywood, I finally had a set of plates which would work for linear rail's as well as keeping some of the rigidity of the wheels. I cut the plates from 1/4" acrylic and one of the first projects for this router will be to create the plates from 1/4" aluminum. Once that's done, I'll convert my diode laser into a small format router with laser attachment in a larger size since I'm not too cheap to order proper rails

So there's my update on what's happening in the edwards shop in these covid times.