-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machine Left the Shop Door Open

- Thread starter ducdon

- Start date

Machine

Cool! Where did you get it? There are a few of us with green machines. We will have to compare notes & start posting learnings.

I have been embarrassingly tardy with mine (Accusize sourced more years ago than I will admit in public). Priorities, priorities. But this winter will be a concerted effort to get up to speed, make it run and I suspect correct some issues I already know are there. I just ordered 20pc set of offshore metric R8 collets. Mostly for the TCG but useful for mill as well. I looked into buying a 5C work head to retrofit TCG because I already have 5C set. But it was not in the stars. Shars will sell but wants a chunk of change to buy separately. I 'think' can source it off Alixpress but its a bit of minefield. The sellers are somewhere between clueless as to what they are even selling, or maybe playing dumb to make a sale, or at best a very wide language barrier gap that has not been closed to where I will gamble $$. Example Ali>you want yellow or green? Peter I don't care about color, is it 5C, R8 or U2 collet? Ali> ok you want yellow one! Peter> is it 5C? Ali> look at picture. Peter> the picture doesn't show a collet, you got my email with parts schematic & big red circle right? Ali> ok green one .....etc. etc.

Meanwhile I've gathered a bunch of Youtube/other web information, manuals etc. Stefan.G & Rob.R are the main guru's that overclocked theirs & have them doing good work. I'm of the opinion the quality varies by seller.

I have been embarrassingly tardy with mine (Accusize sourced more years ago than I will admit in public). Priorities, priorities. But this winter will be a concerted effort to get up to speed, make it run and I suspect correct some issues I already know are there. I just ordered 20pc set of offshore metric R8 collets. Mostly for the TCG but useful for mill as well. I looked into buying a 5C work head to retrofit TCG because I already have 5C set. But it was not in the stars. Shars will sell but wants a chunk of change to buy separately. I 'think' can source it off Alixpress but its a bit of minefield. The sellers are somewhere between clueless as to what they are even selling, or maybe playing dumb to make a sale, or at best a very wide language barrier gap that has not been closed to where I will gamble $$. Example Ali>you want yellow or green? Peter I don't care about color, is it 5C, R8 or U2 collet? Ali> ok you want yellow one! Peter> is it 5C? Ali> look at picture. Peter> the picture doesn't show a collet, you got my email with parts schematic & big red circle right? Ali> ok green one .....etc. etc.

Meanwhile I've gathered a bunch of Youtube/other web information, manuals etc. Stefan.G & Rob.R are the main guru's that overclocked theirs & have them doing good work. I'm of the opinion the quality varies by seller.

gerritv

Gerrit

A wonderful addition to the shop.

I have a 1970's or so Alexander 2CGD, Deckel quality. I have been adding 'features' from Model Engineers Workshop article and also some optics/magnifiers. Mine uses the E355/U2 collets, those I buy from AliExpress. For misc. items I have a 16mm collet with a ER16 collet chuck.

Wheels I buy diamond wheels from AliExpress, stones (Norton etc) from KTS Tooling in Etobicoke.

Buy/make hubs for all the wheels. I had to make mine as real ones are unobtanium

I have a 1970's or so Alexander 2CGD, Deckel quality. I have been adding 'features' from Model Engineers Workshop article and also some optics/magnifiers. Mine uses the E355/U2 collets, those I buy from AliExpress. For misc. items I have a 16mm collet with a ER16 collet chuck.

Wheels I buy diamond wheels from AliExpress, stones (Norton etc) from KTS Tooling in Etobicoke.

Buy/make hubs for all the wheels. I had to make mine as real ones are unobtanium

@gerritv I thought I read somewhere the Alexander was built under license of Deckel, do you happen to know? Seems like more used of that brand pop up vs. Deckel but maybe just coincidence when I was looking. I oscillated back & forth across the financial spectrum between Chinese clone, Taiwan clone & used European. Not sure I made the right choice but I'm committed now.

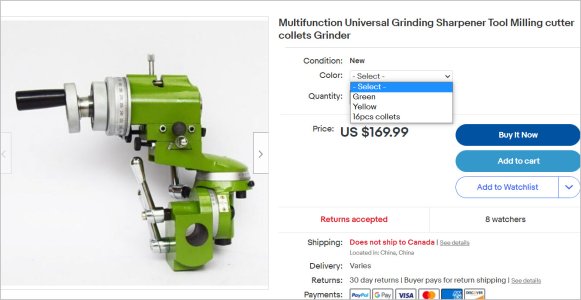

Here is example of a separate work head available. Happens to be Ebay but same on AliExpress. Sometimes their strange color code system actually corresponds to size or standard (wishfully thinking collet format R8, 5C, U2). But sometimes it really does mean PAINT. There is no definitive cross reference so I don't want to gamble. OTOH I have had some ideas of holding other things & this might be a way to buy the 'kit', cannibalize the spindle & not affect the base machine. But that's down the road... I will roll with R8 collet & focus my attention on more important matters - ill fitting grinding wheels & other fixture issues.

Attachments

gerritv

Gerrit

@PeterT I also have heard that rumour/fact. It certainly is superbly made, no gibs on the dovetails is one example. Just precisely made. One thing to watch with the early Alexander and Deckel S0's is not to buy the 16mm collet ones, unless you want to make your own collets. Doable but not fun. Another brand is Kuhlman, blondihacks has one of those.

IMHO the only bad choice is not having one at all

I don't see the collets as limiting, the U2/E355 and 5C's e.g. have a very limited clamping range. So for all the odd ball sizes I use the ER16 which have a broader clamping range. Or I make what ever is needed to hold the cutter, e.g. for gear cutters.

The wheels need hubs, else you are forever truing them on change out.

IMHO the only bad choice is not having one at all

I don't see the collets as limiting, the U2/E355 and 5C's e.g. have a very limited clamping range. So for all the odd ball sizes I use the ER16 which have a broader clamping range. Or I make what ever is needed to hold the cutter, e.g. for gear cutters.

The wheels need hubs, else you are forever truing them on change out.

Attachments

Example Ali>you want yellow or green? Peter I don't care about color, is it 5C, R8 or U2 collet? Ali> ok you want yellow one! Peter> is it 5C? Ali> look at picture. Peter> the picture doesn't show a collet, you got my email with parts schematic & big red circle right? Ali> ok green one .....etc. etc.

This is hilarious Peter! And SOOOOO TRUE TOO!

Mine came from Accusize. The basics look pretty good but quality control sucks. Paint on machined surfaces, swarf in the work head, ugly burs. The work head would hardly move in any direction. I disassembled cleaned, removed paint and stoned all the edges. Machined a new sleeve for grinding wheel. I think it will be fine after some work.Cool! Where did you get it? There are a few of us with green machines. We will have to compare notes & start posting learnings.

I have been embarrassingly tardy with mine (Accusize sourced more years ago than I will admit in public). Priorities, priorities. But this winter will be a concerted effort to get up to speed, make it run and I suspect correct some issues I already know are there. I just ordered 20pc set of offshore metric R8 collets. Mostly for the TCG but useful for mill as well. I looked into buying a 5C work head to retrofit TCG because I already have 5C set. But it was not in the stars. Shars will sell but wants a chunk of change to buy separately. I 'think' can source it off Alixpress but its a bit of minefield. The sellers are somewhere between clueless as to what they are even selling, or maybe playing dumb to make a sale, or at best a very wide language barrier gap that has not been closed to where I will gamble $$. Example Ali>you want yellow or green? Peter I don't care about color, is it 5C, R8 or U2 collet? Ali> ok you want yellow one! Peter> is it 5C? Ali> look at picture. Peter> the picture doesn't show a collet, you got my email with parts schematic & big red circle right? Ali> ok green one .....etc. etc.

Meanwhile I've gathered a bunch of Youtube/other web information, manuals etc. Stefan.G & Rob.R are the main guru's that overclocked theirs & have them doing good work. I'm of the opinion the quality varies by seller.

I have a "hasberg fss" also Deckel clone. Made in Germany. I have made wheel hubs for it and a collet adapter that allows me to use the 10mm Derbyshire collets that I have for my Derbyshire instrument lathe. The spindle takes the Deckel 20mm collets. It is 220 three phase. I have a vfd wired to a receptacle so I can plug in any of my several 3 phase machines when I need them.

Yes I thought of that too. I have an R8-ER collet holder. When I inserted it into my TCG spindle, the alignment set screw jammed up in the groove (set too deep). The R8 collets fit, at least the few I have on hand. I'll have to take the spindle unit apart & see what I can do. If its like the other one I see, looks like they Loctite in place & ground off with a manual disc. I have had this issue before with other R8 tooling. Seems like the groove depth is a bit of manufacturing variable so you have to recess depth for the worst offender in the family.the U2/E355 and 5C's e.g. have a very limited clamping range. So for all the odd ball sizes I use the ER16 which have a broader clamping range. Or I make what ever is needed to hold the cutter, e.g. for gear cutters

Actually thinking about this some more, wouldn't the part insertion depth of R8-ER holder be shallower than an R8 collet with external retention nut? I haven't measured my ER, but I just assumed since its intended for end mills & such, figured the depth limit would be the holder body, maybe 2" insertion?

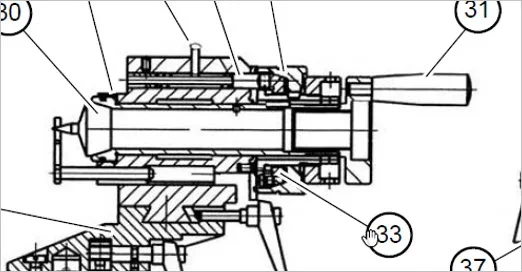

I have not gotten this far yet but I'm hoping the spindle barrel can be removed in which case one could replace with a shop made version. To change from say a R8 to 5C or ER would be a matter of turning new collet angle at front & thread / retention system in rear. Now whether this spindle tube ties into other sleeves or bushings to facilitate pin & indexing, I'm not sure. It might be more involved & wishful thinking at this point.

Attachments

Former Member

Guest

I got mine from Shars though Accusize was a consideration, it had R8's the Shars was 5C (bought a whole bunch of 5c's from Accusize though to cover the size limitations).

When I have time I'm going to work put the center cutting portion for multi flute end mills.

Shars also sells center hubs, bought extras of those as well. I suspect that they will work for the Accusize machine.

When I have time I'm going to work put the center cutting portion for multi flute end mills.

Shars also sells center hubs, bought extras of those as well. I suspect that they will work for the Accusize machine.

I wondered about that.That guy woolvv was a spammer. Importing doors from the UK to Canada? No I don’t think so.