I wanted to check my spindle endplay to see if the taper roller bearings need adjusting. I couldnt find anything specific to my lathe (Standard Modern Utilathe 1654).

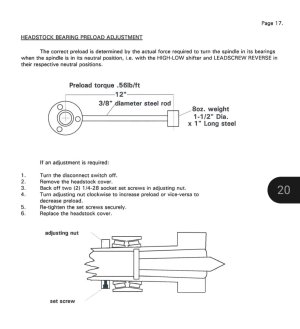

I did find some adjustment torque specs in the Standard Modern 1340 lathe, but on the diagram it seems to show 2 taper roller bearings back-to-back. It tells you to put an 8oz weight on a 3/8" steel rod 12" from the spindle center.

I also read (on-line) that there should be zero play.

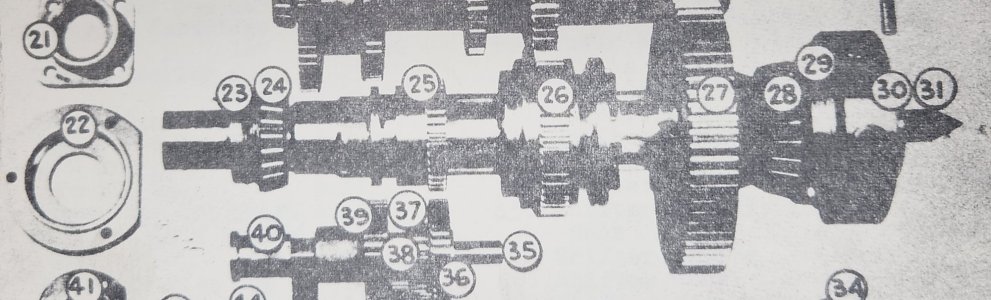

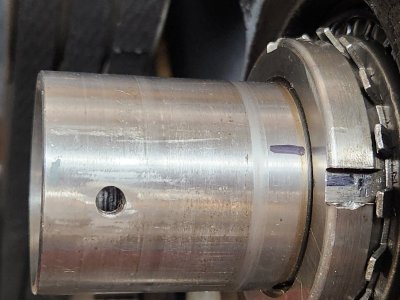

My taper roller bearing are on either end of the spindle, and preload is adjustable. (See picture from my owners manual).

I put all the gearing into neutral.

The lathe has not been run, but it's in my heated garage at 21°C.

I checked for endplay with a piece of wood and I can get almost 0.001" of axial movement with me pulling back on the piece of lumber with not too great of a force 2' out. (I looked around to find my luggage weight gauge to get an accurate-ish number, but it's nowhere to be found....of course)!

I then gripped a 5/16" threaded rod (couldn't find 3/8") in the chuck, and put an 8oz weight at the 12" mark. The spindle easily rotated.

Some feedback from you guys would be extremely helpful please, before I bugger things up.

I did find some adjustment torque specs in the Standard Modern 1340 lathe, but on the diagram it seems to show 2 taper roller bearings back-to-back. It tells you to put an 8oz weight on a 3/8" steel rod 12" from the spindle center.

I also read (on-line) that there should be zero play.

My taper roller bearing are on either end of the spindle, and preload is adjustable. (See picture from my owners manual).

I put all the gearing into neutral.

The lathe has not been run, but it's in my heated garage at 21°C.

I checked for endplay with a piece of wood and I can get almost 0.001" of axial movement with me pulling back on the piece of lumber with not too great of a force 2' out. (I looked around to find my luggage weight gauge to get an accurate-ish number, but it's nowhere to be found....of course)!

I then gripped a 5/16" threaded rod (couldn't find 3/8") in the chuck, and put an 8oz weight at the 12" mark. The spindle easily rotated.

Some feedback from you guys would be extremely helpful please, before I bugger things up.