-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe - Gearbox Oil

- Thread starter Rolln

- Start date

Brett, for what it's worth. I have an older Craftex B2227L 10'x18' lathe and mill drill. Changed the headstock gear oil at new and several times since running Canadian Tire, Motomaster ISO AW 68 Hydraulic Oil. The reason I went with ISO 68 is my garage becomes very warm during summer months. As for a reliable 'Way oil' I also use Motomaster SAE 30 Non Detergent oil. My Craftex lathe and mill/drill do not see heavy usage therefore running hours between oil changes is an overkill on my part. Canadian Tire also carries ISO 32 & 46 AW Hydraulic oil which work just as well. I buy mine in 5L jugs.

I look at it this way an oil change is cheap maintenance that gives me piece of mind. Bill

I look at it this way an oil change is cheap maintenance that gives me piece of mind. Bill

Last edited:

Brett, you sure don't want to be running engine oil meaning a detergent oil in your gear head. Bill

Yup, non-detergent SAE 30 in mine.

The manual for my King KC1236ML, which is the King equivalent, specifies AW32 oil in the apron but nothing specific about the headstock. However, the Grizzly G4003 manual (basically the same machine as both of ours) specifies ISO32 oil in the headstock and ISO68 in the apron. I have followed the Grizzly manual in servicing my lathe as the machine looks identical to mine but green instead of gray, and their manual is much better written, has more information, and is illustrated better. Using Shell Tellus AW32 in the headstock and the AW68 in the apron. Hope this helps rather than makes things muddier.

Sorry for the aside, but I can't resist laughing whenever I see that phrase, as the bar is so low to begin with.and their manual is much better written, has more information, and is illustrated better.

I used to collect bad manuals, and my favourite was an original owner's manual from a Model T Ford. On the page for "Refilling Petrol" it said:

- Remove petrol cap.

- Insert petrol hose into orifice.

- ...

- ...

- ...

- ...

- ...

- ...

- ...

- Note: Before performing the above 9 steps, extinguish all smoking materials.

Here's another manual from Precision Mathews.

https://www.precisionmatthews.com/wp-content/uploads/2017/02/PM-1236-v4-1-2017-indd.pdf

https://www.precisionmatthews.com/wp-content/uploads/2017/02/PM-1236-v4-1-2017-indd.pdf

Tom Kitta

Ultra Member

ISO 32 - hydraulic oil for speeds under around 2000 rpm, 22 for speeds max just over 2000 and 15 for speeds at 3000 rpm. Unless you spin always around say 1700 rpm - then just iso 15 or less (such as oil filled engine). For gearboxes in say apron you can go heavier - say ISO 68.

I also run ISO 32 in my old Chinese lathe - 089 - I see above BB said SAE 30 which is around ISO 90 - there is a reason that lathe did throw a breaker when started at speeds > 700 when cold.

If your garage is very hot you may go one grade up - if your garage is -20C you may go one grade down. If you never run at higher speeds - can go one up.

I buy my ISO grade oils at princes auto in 20L jugs. Except for ISO 15 - I got 1L from a very friendly member here.

For way oil I use heaviest oil I can find - usually SAE 90+ Actual way oil would be better.

Most hydraulic oils have viscosity modifiers - some a lot - allowing them to keep their viscosity even when it gets very cold. Running heavy oil in a lathe will use far more energy then needed plus it will not create lubricant mist as well. This only may become a problem when you run a lathe at close to top speed for longer period of time.

Basically when things move slow you want heavier oil to stick to the gear longer - vs. fast moving gear where that sticking is not needed (as new oil is added all the time). Note that some parts of a lathe are run at high speed all the time - while others run slow or fast. Also lathe may be run on same oil both in summer and winter - hence its all a giant compromise of what one will pick.

Finally generally older machines have specifications in their manuals as I give above while newer machines of mostly Chinese origin have much heavier oils.

I also run ISO 32 in my old Chinese lathe - 089 - I see above BB said SAE 30 which is around ISO 90 - there is a reason that lathe did throw a breaker when started at speeds > 700 when cold.

If your garage is very hot you may go one grade up - if your garage is -20C you may go one grade down. If you never run at higher speeds - can go one up.

I buy my ISO grade oils at princes auto in 20L jugs. Except for ISO 15 - I got 1L from a very friendly member here.

For way oil I use heaviest oil I can find - usually SAE 90+ Actual way oil would be better.

Most hydraulic oils have viscosity modifiers - some a lot - allowing them to keep their viscosity even when it gets very cold. Running heavy oil in a lathe will use far more energy then needed plus it will not create lubricant mist as well. This only may become a problem when you run a lathe at close to top speed for longer period of time.

Basically when things move slow you want heavier oil to stick to the gear longer - vs. fast moving gear where that sticking is not needed (as new oil is added all the time). Note that some parts of a lathe are run at high speed all the time - while others run slow or fast. Also lathe may be run on same oil both in summer and winter - hence its all a giant compromise of what one will pick.

Finally generally older machines have specifications in their manuals as I give above while newer machines of mostly Chinese origin have much heavier oils.

Dabbler

ersatz engineer

+1 to all Tom's comments.

To keep things simple I run 2 oils: AW32 and Tonna 68. I run AW32 in everything, aprons, gearboxes and headstocks. On all ways I use Tonna Way Oil. The reason is that it doesn't run off the ways -horizontal or vertical - for many days.

Having just 2 makes it really easy. I buy a 5 gallon AW32 from princess auto when I run out (and I do). I have a 5 gallon Tonna 68 which will last me another 20 years.

Yes, you can run way oil in gearboxes quite safely. STP is just stiction additives to normal oil, and it's been used in gearboxes for nearly 50 years.

To keep things simple I run 2 oils: AW32 and Tonna 68. I run AW32 in everything, aprons, gearboxes and headstocks. On all ways I use Tonna Way Oil. The reason is that it doesn't run off the ways -horizontal or vertical - for many days.

Having just 2 makes it really easy. I buy a 5 gallon AW32 from princess auto when I run out (and I do). I have a 5 gallon Tonna 68 which will last me another 20 years.

Yes, you can run way oil in gearboxes quite safely. STP is just stiction additives to normal oil, and it's been used in gearboxes for nearly 50 years.

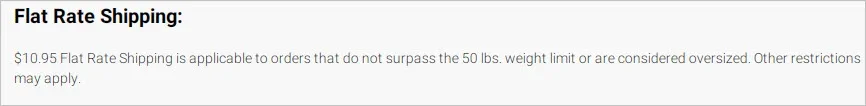

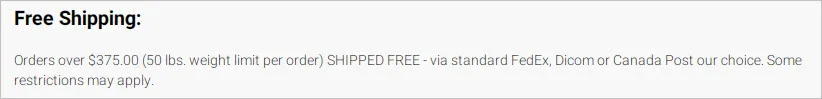

KBC has way oil from SAE 10 to 50 in 1 gallon (US) containers for 26.00 CDN and they have a 10 dollar shipping policy so I usually add a few extra items.

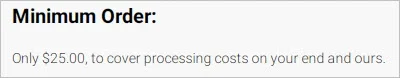

They have a $50 min order policy as well as a $10 shipping.

Last edited:

According to the website...

https://www.kbctools.ca/company/terms-of-sale

https://www.kbctools.ca/company/terms-of-sale

Attachments

According to the website...

https://www.kbctools.ca/company/terms-of-sale

Hmmm..... I swear it wouldn't let me checkout until I had $50 worth of stuff in my cart???