-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe DRO-Aikron A30 LCD

- Thread starter thestelster

- Start date

And doing a fantastic job of it I might add!!We're here to spend your money!

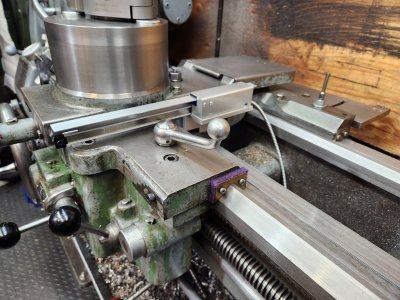

Well, I started the install. The x-axis is in, plus the covers. I might figure out a better cover, but its fine for now...until it isn't!

Attachments

TorontoBuilder

Ultra Member

I dont know about you and tom... I prefer to look to my left.Well, I started the install. The x-axis is in, plus the covers. I might figure out a better cover, but its fine for now...until it isn't!

Honestly, I don't know where to put the screen, so I'm going to have to experiment as time goes by. I have my most often used tools on a wooden platform on top of the head stock, and switching tools is quite fluid and quick process, so the screen won't fit in that area.I dont know about you and tom... I prefer to look to my left.

Attachments

Interesting. I have my Shumatech DRO-350 to the left of the head on my mill. But the CNC PC keyboard, mouse and screen are on the right. More a space issue than a choice of preference since I don't know my preference.I dont know about you and tom... I prefer to look to my left.

I think on the lathe I'd rather have the display to the right. But I'm not sure why...

OTOH, I can see that if I'm looking at the tool tip entering the work and the DRO is just in the same direction of sight it would be useful.

OTOH, I can see that if I'm looking at the tool tip entering the work and the DRO is just in the same direction of sight it would be useful.

I dont know about you and tom... I prefer to look to my left.

Honestly, I don't know where to put the screen, so I'm going to have to experiment as time goes by.

I'm planning to put my display right ABOVE the headstock. I plan to make a double sided wooden hat out of clean maple to match my tool holder rack. I love the marriage of wood and metal.

One side of the hat fits over the headstock like any hat would, and can be clamped down if necessary. The other side of the hat acts like a flat shallow sided tray to hold tools and other things I need handy to the lathe. Could be tool holders like yours, or whatever. Because there are shallow sides on the top of the hat, the tools will never fall off. I might drill a few holes to add Allen wrenches, screw drivers, or whatever. The left side of the top will be taller and have an anchor to hold my DRO Display. I want the display on the left so I can glance from the part to the display without turning my head. A lot of intense things happen at the chuck jaws. I don't want to be looking elsewhere.

I also don't want the display in the line of fire from hot swarf or whatever. So it will be attached at the left side of the hat and sit above the left side.

Edit - I forgot to add the little detail that led me to this solution. I do not want to drill and tap holes in my headstock to hold a display mount. Too much risk of punching through into the oil box. A hat needs no screws to hold it in place and then the mount can be screwed to the wooden hat.

Last edited:

This is the way: it is directly in my line of sight, just need to glance up. Or, as I do more and more, I just watch the DRO, not the tool. No sign of cutting fluids on the cover.

No way that would work for me @gerritv . My backsplash and the whole wall behind my lathe has a racing stripe on it. I cannot even begin to imagine how you keep yours so clean. I'll take a picture tomorrow and add it to this post.

Why are there two different displays. One on the left and the one behind the headstock.This is the way: it is directly in my line of sight, just need to glance up. Or, as I do more and more, I just watch the DRO, not the tool. No sign of cutting fluids on the cover.

gerritv

Gerrit

Rocketronics ELS over the headstock, Aikron DRO to the right. I'm mostly lefthanded so the layout works well for meWhy are there two different displays. One on the left and the one behind the headstock.

TorontoBuilder

Ultra Member

thems fightin wordsI keep things clean by not hosing on the coolant/cutting oilJust enough to do the job.

Crappy pic but mine is oriented like so. Just right of the chuck jaws, which seems to be where my attention is focused most of the time. So its a quick vertical-ish nod up & down between DRO & work. I can swing the display away it if I'm expecting spray. I found that using thicker viscosity fluid & (not in picture) backsplash helped. But the DRO competes for spatial real estate with the (LED converted study) light. Ceiling LEDs replacing fluorescents helped a lot but I still prefer a local light, so I haven't solved that yet. I think I require what amounts to a Noga arm but at 1/10 the cost.

I keep things clean by not hosing on the coolant/cutting oilJust enough to do the job.

I don't like it all over the place either so I'm already careful not to use more than I need. I found that thicker fluids helped. I usually just apply it very sparingly with a brush or a small dropper can.

I don't know how you manage to avoid racing stripes.