As posted earlier

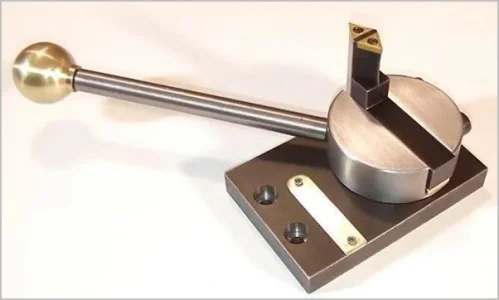

@eotrfish and I came to an agreed price and I got this lantern style ball turner from him. It arrived yesterday.

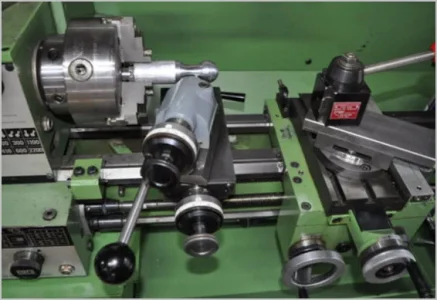

Now it's time to adapt it to my BXA Toolpost lathe.

The top and bottom of the rocker bar are already flat and the sides are pretty good. Not at all like my other lantern style tools. So right now I'm thinking about making a special tool holder for it instead of trying to adapt it to a 5/8 holder by adding a 5/8 bar to the side of the lantern bar. I can, either machine an existing 5/8 holder for it or make an all new one.

So I measured it all up and decided I'll prolly go with making the 5/8 slot in a tool holder a bit bigger to accept the lantern bar.

The bottom of the lantern bar needs to be about 1/2 inch above the base of the tool post (top of the cross-slide) to put the cutter on center of the spindle.

I'm also thinking that it might work best mounted on the right side of the tool post instead of the more traditional back or left side. Again, I'll have to rig it up to get a real sense of it. But that doesn't change the need to make a tool-holder adapter.

If I position the bottom of the blade 1/2" above the bottom of the tool holder, I am left with about 1/4" at the top.

I can't imagine any ball turning job that would require big heavy cuts. So right now, I'm thinking that it all works out pretty darn good!

Edit - For reference, the holder is 1.75 high, and the lantern bar is 2 thou under an inch.

Other thoughts?