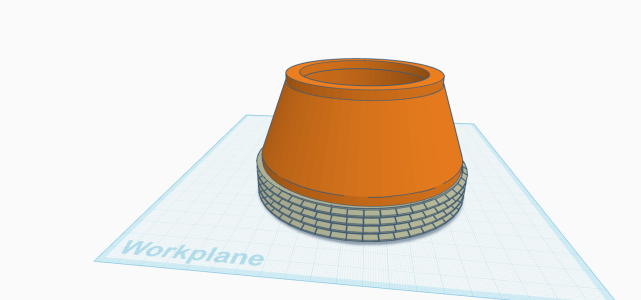

I made a metal drawbar and collet adaptor for some 5C collets for my Colchester lathe and now I need to 3D print a spindle cover. The cover will protect the L0 taper and secure the large spindle nut from flopping around when using the lathe. Printing and Cad work is all new to me but I am making some progress. To prevent 3D printed junk I like to print 1mm thin test piece and check for fitment. I can quickly print these test pieces and make adjustment if needed.

I used thinkercad to design it because that is the only cad I know how to use. I used a thread generator from maker world (https://makerworld.com/en/models/485168?from=search#profileId-401735) to make the 4 1/2" - 6TPI ( part 1). It fitted the spindle nut but very tightly, a bit of filling with a 60' profile and it fitted nicely. Then I made some really thin test print to check the fitment of the taper ( part 3, 4a, 4b, 5) and then the taper keyway fitment (part 5) . Now I have all the parts tested, I assembled them and pushed the print button. I will know the result in 8 hrs, crossing my fingers !

I used thinkercad to design it because that is the only cad I know how to use. I used a thread generator from maker world (https://makerworld.com/en/models/485168?from=search#profileId-401735) to make the 4 1/2" - 6TPI ( part 1). It fitted the spindle nut but very tightly, a bit of filling with a 60' profile and it fitted nicely. Then I made some really thin test print to check the fitment of the taper ( part 3, 4a, 4b, 5) and then the taper keyway fitment (part 5) . Now I have all the parts tested, I assembled them and pushed the print button. I will know the result in 8 hrs, crossing my fingers !