-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

King 1440 and Craftex Threading

- Thread starter cuslog

- Start date

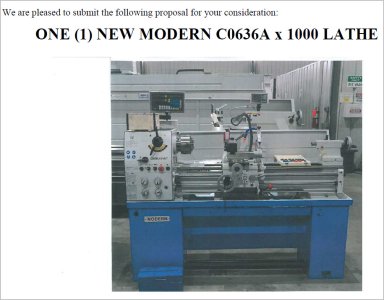

Looks identical to the C0636 I bought from Modern tool in Calgary about 2004. Just different color paint and decals.

No quick change gearbox - always annoyed me to do any threading.

I'm not following - don't you select the thread pitch with knob combinations, engage the thread vs powerfeed lever, engage the threading clamshell lever & proceed threading?

Not the one I had, the 4 smaller knobs on the bottom just varied power feed speeds. Any threading, I had to take off the end panel and change out 3 gears (using 3 different wrenches), replace the end panel, cut threads then reverse the process to get power feeds back.

Hmm.. Maybe a model number difference between C0636 and C0632A maybe? I have the C0632A manual it it discusses threading pretty much like most lathes of this size. The gear change is only required for metric/imperial threading, again like most lathes with imperial feed screw.Not the one I had, the 4 smaller knobs on the bottom just varied power feed speeds. Any threading, I had to take off the end panel and change out 3 gears (using 3 different wrenches), replace the end panel, cut threads then reverse the process to get power feeds back.

I have the C0632A manual it it discusses threading pretty much like most lathes of this size. The gear change is only required for metric/imperial threading, again like most lathes with imperial feed screw.

I dunno about that "like most lathes with imperial screw" comment Peter. Mine has the 127/100 set to change to metric just like you describe. But it also uses a combination of 4 other external gears (6 with the 100/127). Yes, there are 4 Knob Dials to change internal gears to further refine the desired thread pitch. But these are used together with the 4 external gears.

I've also seen many older lathes with a pile of gears - a few dozen!

Yes, mine was probably "the cheaper model". First lathe I'd ever owned, didn't know any better when I bought it. Was actually a decent machine but I always mumbled to myself when it came time to single point threads - could do it but it sure interrupted the work flow. Yes, probably a dozen or so loose spur gears in the tool box that came with it.

I dunno about that "like most lathes with imperial screw" comment Peter. Mine has the 127/100 set to change to metric just like you describe. But it also uses a combination of 4 other external gears

My comment was not intended to distinguish imp/met threading or accessing other threads via gears. It was in response to his comment that he has to change gears in order to thread. Which I don't quite understand but I'm not familiar with the model. Sounds like its either a workaround way of disengaging the power feed or alter the power feed to correspond to a different pitch?

Anyway the model C0632A was referenced (because it resembles the lathe originally posted, the primary subject of this post) as though it lacked switch mode power feed / threading & I don't think that's true. So maybe older vintage, similar model number? Or that's what the 'A' means? All I have to go on is the manual from Modern & that's several years old now.

Any threading, I had to take off the end panel and change out 3 gears (using 3 different wrenches), replace the end panel, cut threads then reverse the process to get power feeds back.

My comment was not intended to distinguish imp/met threading or accessing other threads via gears. It was in response to his comment that he has to change gears in order to thread.

Too funny. I think we both took different meanings.

I thought you were saying most lathes don't use change gears anymore - just the 127/100 for metric.

Mine is pretty new, and has both internal and external gears to set thread pitch. I think that's pretty common on most smaller (14 and under) gear heads.

But I lied about the number of external gears I have for mine. It's actually 10 gears if you include the 127/100. The 127/100 is always installed either as 127/100 or as 100/127. Two of the others are also always installed, so it's really 8 not 6. They are 54 57 60 60 63 66 69 78 100 127.

Sorry for the confusion.

Actually, I didn't lose power feeds, they were just so far off (in speed) as to be essentially useless.

Any chance you left the metric gears reversed? That would royally screw up your feed speeds. I'm guessing mine are about 60% different (although I didn't measure it).

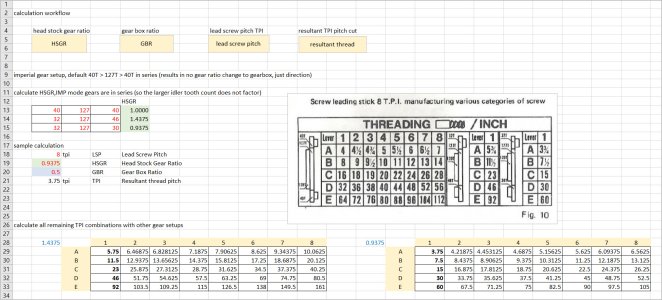

That's exactly what I was wondering. Its been a while since I looked at my homebrew calculator but depending on how you swap the gears around, it's possible to get different nominal pitches as intended, but maybe also possible to get unintended incorrect pitches/feeds. The plate they nail to the machine typically shows nominal sizes but not all possible sizes. Sadly, some of the common metric pitches on my machine are not possible. Too bad there wasn't an quick & easy way to swap in a metric pitch feed screw. But you'd need a disconnect coupler on the HS side, metric clamshell set, dismantle the TS side shaft block..yadayada. I'm not that ambitious, wait for @Janger to finish his ELS!

Attachments

Well, I don't think so, one of the gears had 2 sets of teeth, one side 100 teeth, the other 127, it was quite obvious which side had more teeth and IIRC, the 127 side was some kind of a metric conversion gear, the 100 side for TPI threads. I don't think I ever used the 127 side because I don't think I ever cut metric threads on that machine and when I used the 100 side, I got TPI results as per the charts.

Its been a while since I looked at my homebrew calculator but depending on how you swap the gears around, it's possible to get different nominal pitches as intended, but maybe also possible to get unintended incorrect pitches/feeds. The plate they nail to the machine typically shows nominal sizes but not all possible sizes. Sadly, some of the common metric pitches on my machine are not possible.

One of the first things I did when I got my second lathe was to make a chart of all the possible combinations. Just like you, that was an outcome of noticing that the factory chart had missing spots. I found a few others too.

Which common metric ones are you missing? I'd like to check mine. I promise not to gloat if mine has them.

I know sitting here right now that I have 1.6mm on my lathe. I've been told by some that 1.6mm isn't a recognized metric pitch. Yet I have seen this pitch used on several pieces of hardware, and it exists on many of my charts. I think most deniers just want to believe that its really 16tpi because they are VERY close.

Well, I don't think so, one of the gears had 2 sets of teeth, one side 100 teeth, the other 127, it was quite obvious which side had more teeth and IIRC, the 127 side was some kind of a metric conversion gear, the 100 side for TPI threads. I don't think I ever used the 127 side because I don't think I ever cut metric threads on that machine and when I used the 100 side, I got TPI results as per the charts.

Yes, that's the one that might be the culprit. But, you can put that gear in both ways and still get imperial threads. It all depends on whether the mating gear is installed with a bushing or not to determine which of the two gears drives the feed system. So, you might still have it upside down and/or you might not have the bushing installed on the mating gear correctly.

I think that your miles off feeds are a clear give away that something like that is wrong.

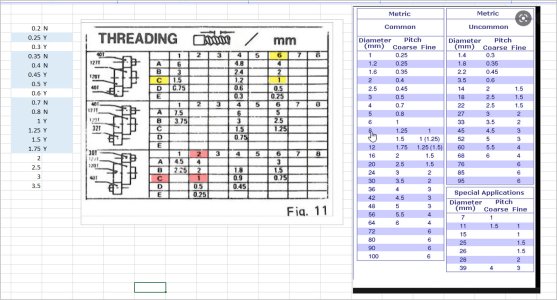

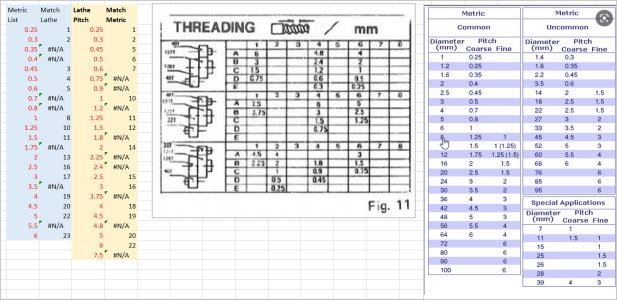

Hmm.. this is reminding me I left this project unfinished, but I think its pretty close. Where it shows an integer is a match between what my lathe can do & known metric pitch, common & uncommon accordingto the table I imported. For completeness there are some other pseudo-nominal pitch combinations lathe can do but I suspect not typical metric pitches. I calculate this on another sheet but seems like my MATCH or VLOOKUP function is not playing nice today, I'll have to dig deeperWhich common metric ones are you missing? I'd like to check mine. I promise not to gloat if mine has them.

Attachments

I have the c0636a, and @cuslog experience is like mine. Each gear combo can do a handful of pitches, but not all. Eventually you have to change gears. The power feed speeds shown correspond to a specific gear combination (30 and 60 I believe). When you change the gears the feed chart isn’t relevant I believe.

I have the c0636a, and @cuslog experience is like mine. Each gear combo can do a handful of pitches, but not all. Eventually you have to change gears. The power feed speeds shown correspond to a specific gear combination (30 and 60 I believe). When you change the gears the feed chart isn’t relevant I believe.

I think one of the things that messes with our heads on this is that there is a gear set in the saddle. When you engage the half nut, the saddle exactly follows the lead screw. You can watch the screw turn and the saddle movement at the left edge of the saddle where it meets the lead screw. The saddle moves as though it were following the leade screw pitch. Because it is!

On the other hand, if you engage the longitudinal power feed, you can see that the saddle does not follow the pitch of the leade screw. Instead it follows it according to its internal gear ratio.

So the thread pitch isn't the same as the feed rate unless the half nut is used to control feed - which I don't do.

On the gear set side of the lathe head, the leade screw is turned by the external gear set combo as well as any internal gear set combo. Together they set the leade screw rotation in relation to the spindle rotation. To cut a 16 TPI thread, the carriage must move 1/16 of an inch for each full turn of the spindle.

You guys have this model C0636A? Maybe I spoke too soon without reading the fine print.I have the c0636a, and @cuslog experience is like mine. Each gear combo can do a handful of pitches

(left pic) is it the a&b gear swap you are talking about?

(right pic) is my 14x40, all the pitches possible with 40-127-40 tooth gear combo, just engage the letter/number gearbox banjo levers

So If I want to to 20 TPI I engage C-4. But you have to mount gears 60-57 if you were in 60-60, that is not a lever select?

Attachments

You guys have this model C0636A? Maybe I spoke too soon without reading the fine print.

(left pic) is it the a&b gear swap you are talking about?

(right pic) is my 14x40, all the pitches possible with 40-127-40 tooth gear combo, just engage the letter/number gearbox banjo levers

I don't see a left and right pic in your post Peter.

I'm really only trying to help @cuslog fix his feed speed issue.

@John Conroy while we're on the subject, does this metric pitch availability look right to you - between your old (my current) 14x40 & your GH?