Proxule

Ultra Member

Hey fellas,

I am in a pickle. I hate king Canada, But KMS has been very good to me with prior machine parts and support.

I missed the price jump on the PM1236 machines not long ago. As it stand if I want the PM1236 PEP with cast iron stand and shipped to my door its exactly $7200 CAD ( all in )

WAAAAY too much for a 1236 lathe. I don't really need a feed clutch and coolant pump.

Brake is nice and a light. But the gear box does require you to change it up if you are doing work outside the envelope.

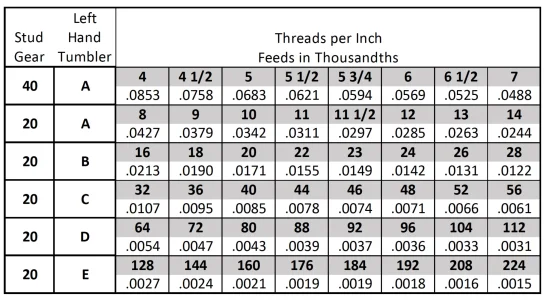

The KING CANADA 1236 is a norton gearbox. So no gear swapping until you want to cut bastard metric thread, haha!

It has the regular things like a sheet metal stand, QCTP etc etc. It really is identical to the G4003 lathe.

THe price tag is $ 5350 ( $5617 all in ) on the KC1236

Any one actually own one of these, The local KMS is out of stock for a bit so I cant actually fiddle with the norton gearbox or feel the machine up.

Are the cross slide and compound scraped like the PM1236?

Any thought or opinions, I am sure this topic has been discussed before but nothing really shows up on search.

Thanks guys

I am in a pickle. I hate king Canada, But KMS has been very good to me with prior machine parts and support.

I missed the price jump on the PM1236 machines not long ago. As it stand if I want the PM1236 PEP with cast iron stand and shipped to my door its exactly $7200 CAD ( all in )

WAAAAY too much for a 1236 lathe. I don't really need a feed clutch and coolant pump.

Brake is nice and a light. But the gear box does require you to change it up if you are doing work outside the envelope.

The KING CANADA 1236 is a norton gearbox. So no gear swapping until you want to cut bastard metric thread, haha!

It has the regular things like a sheet metal stand, QCTP etc etc. It really is identical to the G4003 lathe.

THe price tag is $ 5350 ( $5617 all in ) on the KC1236

Any one actually own one of these, The local KMS is out of stock for a bit so I cant actually fiddle with the norton gearbox or feel the machine up.

Are the cross slide and compound scraped like the PM1236?

Any thought or opinions, I am sure this topic has been discussed before but nothing really shows up on search.

Thanks guys