Brian G

Member

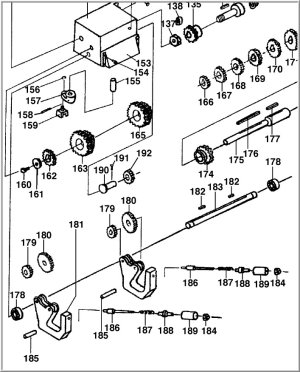

Due to an unfortunate incident while moving the machine, I am going to have to replace the cast shift levers (#181) in the gear box.

Can anyone tell me how to remove the shaft (#183) on which these levers swing?

There is some sort of cover at the outside of each of the shaft bearings (#178), and I cannot see how to remove these covers without sacrificing them. These covers do not appear in the parts list.

Can anyone tell me how to remove the shaft (#183) on which these levers swing?

There is some sort of cover at the outside of each of the shaft bearings (#178), and I cannot see how to remove these covers without sacrificing them. These covers do not appear in the parts list.