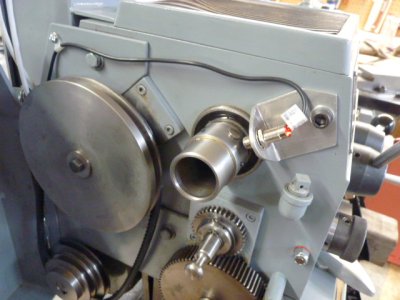

My BB 10" x18" Craftex lathe didn't come with a digital tachometer so I picked up a kit to do that. With everything being mapped out I have made the bracket to hold the 'Digiten' brand sensor in the gear change compartment. Plan is place the magnet(s) on my spindle outer nut edge then line up with the sensor. Unfortunately said outer nut edge is syndical. The not so strong 12mm diameter x 2mm thick magnet that came with my kit is placed on the outer spindle nut so I spin the spindle at top speed and the magnet stayed in place and didn't move.

So where am I going with this, my only concern is over time the magnet weakens and centrifugal force throws the magnet into the gearing. I can go to a much stronger 10mm diameter x 3mm thick magnet which is a much better fit on the nut edge. I doubt the sensor will balk at my using a smaller diameter magnet.

Can also add a drop of lock tight to the bottom of the magnet which should help?

Then what about spindle balance should I use an apposing magnet on the outer nut for balance?

The tachometer box mount is a portable micro plug-in type connecting with the sensor as far as wiring goes.

Suggestions welcome.

So where am I going with this, my only concern is over time the magnet weakens and centrifugal force throws the magnet into the gearing. I can go to a much stronger 10mm diameter x 3mm thick magnet which is a much better fit on the nut edge. I doubt the sensor will balk at my using a smaller diameter magnet.

Can also add a drop of lock tight to the bottom of the magnet which should help?

Then what about spindle balance should I use an apposing magnet on the outer nut for balance?

The tachometer box mount is a portable micro plug-in type connecting with the sensor as far as wiring goes.

Suggestions welcome.

Last edited: