I was looking for some industrial felt to replace the way wipers on the Clausing.

Found these folks in ON: https://thefeltstore.ca/

Found these folks in ON: https://thefeltstore.ca/

are you going to precision cut these with the laser cutter?I was looking for some industrial felt to replace the way wipers on the Clausing.

Found these folks in ON: https://thefeltstore.ca/

I might... I'd have to try a sample first to see how it cuts.are you going to precision cut these with the laser cutter?

I was wondering how I'd cut felt to size for wipers, and figured that would be the best option.

it should cut easier than their nomex feltI might... I'd have to try a sample first to see how it cuts.

Unfortunately unless you have a business licence MMC will not ship to Canada.McMaster Carr has a selection of felts but with different designations. I bought their F-13 which is intended for wipers. Link:MMC Industrial Felt

They use a different standard, and sadly they use a different density measurement as well... but I suspect this is equivalent or closeMcMaster Carr has a selection of felts but with different designations. I bought their F-13 which is intended for wipers. Link:MMC Industrial Felt

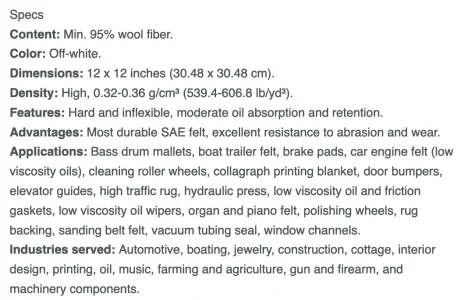

The Felt Store lists a different density for their F1 felt.

View attachment 33652

F-1 Industrial Felt Sheet - 12” Square

The Felt Store’s high-quality SAE industrial felt squares are 12” by 12” and available a variety of densities and thicknesses. For design as well as technical purposes. Order today!thefeltstore.ca

Wool actually absorbs the oil and then releases it as needed as compared to synthetics which does not absorb oil.Why is wool content desirable for oil wipers?

I would have guessed that the spaces between the fibers hold most of the oil compared to what is actually absorbed by the fibers themselvesWool actually absorbs the oil and then releases it as needed as compared to synthetics which does not absorb oil.

Wool fibers are naturally resilient and can withstand repeated compression and use without losing their shape or effectiveness. Wool content is also desirable for oil wipers due to its natural absorbency. Wool fibers are naturally hydrophilic, meaning they have an affinity for water and can trap moisture keeping it off ways. The density used for wipers has a plenty of voids for holding and distributing oil as well.Why is wool content desirable for oil wipers?