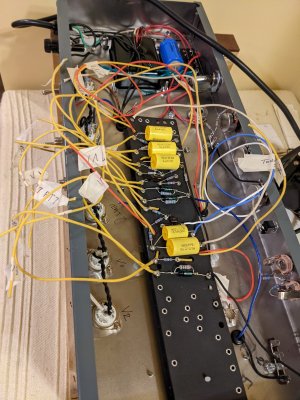

My almost finished guitar amp project. It made noise for the first time today. The metal working component is the fabrication of the chassis. Also includes are some cabinetry, upholstery and good old tube electronics. Still more cabinetry and upholstery to finish.

Attachments

-

IMG_20201120_123418.jpg233.5 KB · Views: 21

IMG_20201120_123418.jpg233.5 KB · Views: 21 -

PXL_20220222_025950459.MP.jpg495.5 KB · Views: 22

PXL_20220222_025950459.MP.jpg495.5 KB · Views: 22 -

PXL_20211221_032133442.jpg454.4 KB · Views: 24

PXL_20211221_032133442.jpg454.4 KB · Views: 24 -

PXL_20210831_003014146.jpg410.4 KB · Views: 23

PXL_20210831_003014146.jpg410.4 KB · Views: 23 -

IMG_20210705_180252.jpg312.3 KB · Views: 20

IMG_20210705_180252.jpg312.3 KB · Views: 20 -

IMG_20201128_143603.jpg266.5 KB · Views: 18

IMG_20201128_143603.jpg266.5 KB · Views: 18 -

IMG_20201128_143545.jpg395.1 KB · Views: 18

IMG_20201128_143545.jpg395.1 KB · Views: 18 -

IMG_20201120_123426.jpg198.1 KB · Views: 16

IMG_20201120_123426.jpg198.1 KB · Views: 16