Couldn’t do this again if I tried. My lathe chuck is held on by three shouldered hex nuts. My bench is custom made from step racking. I dropped one of the nuts. Took fifteen minutes to find it. Sigh.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Impossible Location

- Thread starter whydontu

- Start date

This is the Black Hole on my lathe..... right under the chuck......

Loose something in there (which I have) and it's trapped under the Head Stock. You might retrieve it with a magnetic wand or not. I stuff a rag in that gap (if I remember) when I'm doing something fiddly up top.

Loose something in there (which I have) and it's trapped under the Head Stock. You might retrieve it with a magnetic wand or not. I stuff a rag in that gap (if I remember) when I'm doing something fiddly up top.

You guys should try farming. Finding stuff that fell off (parts, nuts, bolts, etc) especially into grass or plowed dirt, is my biggest occupation, right before figuring out where I put stuff on purpose (glasses, phone, parts, tools).

Ya, @whydontu, that was a weird one for sure! I'm not sure I would have ever found it. Have you figured out how it got there?

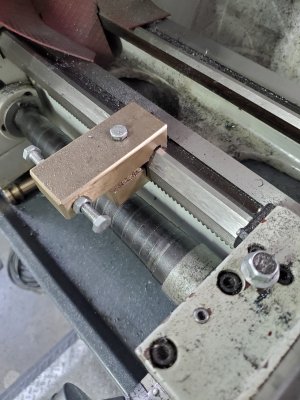

@YYCHM - what's that piece of metal at the lower left with the two blue lines on it?

Ya, @whydontu, that was a weird one for sure! I'm not sure I would have ever found it. Have you figured out how it got there?

@YYCHM - what's that piece of metal at the lower left with the two blue lines on it?

Carriage stop.

I see. It never ever occurred to me to install a stop. But I do plan to make an indicator holder so I know where I am.

A stop like that would bind the feed system or the half nut on my lathe and could do more harm than good under those circumstances. But still maybe better than crashing into the head.......

But maybe your lathe doesnt bind up like mine does when you try to stop it externally......

How often do you actually use the stop?

DPittman

Ultra Member

You can combine the two in one...having a hard stop and an indicator built into as well.I see. It never ever occurred to me to install a stop. But I do plan to make an indicator holder so I know where I am.

A stop like that would bind the feed system or the half nut on my lathe and could do more harm than good under those circumstances. But still maybe better than crashing into the head.......

But maybe your lathe doesnt bind up like mine does when you try to stop it externally......

How often do you actually use the stop?

Here is my version of one and initially I considered building in a indicator in as well but I have dro scales on my lathe so it is unnecessary.

Yes you don't want to use a carriage stop with power feed but that is an easy problem to avoid. You simply slide it out of the way.

Attachments

I see. It never ever occurred to me to install a stop. But I do plan to make an indicator holder so I know where I am.

A stop like that would bind the feed system or the half nut on my lathe and could do more harm than good under those circumstances. But still maybe better than crashing into the head.......

But maybe your lathe doesnt bind up like mine does when you try to stop it externally......

How often do you actually use the stop?

It will bind my feed system as well if I crash into it under power, but I figure that's better than crashing into the chuck. It does give a little so it's not a dead stop. I use it quite a bit but mostly when threading as a safety net per say.

Last edited:

Only thing I can figure is it bounced off the playground mat and into the pocket. One of you engineer dudes should do the math to work out the trajectory of a multi-surface steel component bouncing off a rough textured low-durometer uneven polymer surface. Could keep your mind occupied for years and stave off old-guy brain.You guys should try farming. Finding stuff that fell off (parts, nuts, bolts, etc) especially into grass or plowed dirt, is my biggest occupation, right before figuring out where I put stuff on purpose (glasses, phone, parts, tools).

Ya, @whydontu, that was a weird one for sure! I'm not sure I would have ever found it. Have you figured out how it got there?

@YYCHM - what's that piece of metal at the lower left with the two blue lines on it?

Only thing I can figure is it bounced off the playground mat and into the pocket. One of you engineer dudes should do the math to work out the trajectory of a multi-surface steel component bouncing off a rough textured low-durometer uneven polymer surface. Could keep your mind occupied for years and stave off old-guy brain.

Seems like you have it figured out pretty well. No need for any complicated math.

The basic trajectory is actually pretty easy. It's no big problem at all when you know the exact inputs. It's the billions of combinations of possible inputs that make it complicated. That kind of project is usually best tackled by physicists. They do useless solutions with billions of near zero probability inputs all the time. Engineers prefer to focus on practical applications that solve real world problems - like figuring out how to design a system that can't fall off and get lost in the first place.

If you make one, may as well make two. Its useful to have one on the other side of carriage like when you are turning a recess between 2 reference dimensions.

I also like the sprung quick release clamp where the handle can be positioned or rotated out o the way.

I don't think driving into these under power feed is a good idea, clutch or no clutch. I disengage beforehand & then just kiss it manually.

I also like the sprung quick release clamp where the handle can be positioned or rotated out o the way.

I don't think driving into these under power feed is a good idea, clutch or no clutch. I disengage beforehand & then just kiss it manually.