-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How

- Thread starter DPittman

- Start date

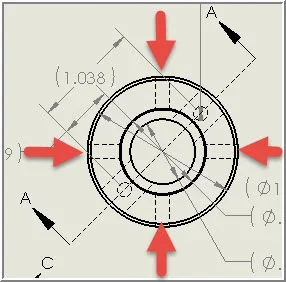

Here is a set I did a while back. The same set screw orientation crossed my mind. For better or worse I made 4 positions at 90-deg. In the absence of any indexing equipment, you could drill one (tap) hole, then put a locating pin/drill in there so its square to vise base & drill opposing hole. Now you have 2 holes to reference flat etc. Its maybe not as precise,

http://canadianhobbymetalworkers.com/threads/die-holders.297/

If there is some 'standard' to the set screws I must have a mixed bag. Even my die stocks have angles that don't match my dies & visa versa. Seems to me most of my dies have 2 dimples at the quadrants & the split is in between. Some dies have a cross bolt that sets the closure so ideally engaged as many dimples as possible with the set screws. I might be out to lunch on all this.

http://canadianhobbymetalworkers.com/threads/die-holders.297/

If there is some 'standard' to the set screws I must have a mixed bag. Even my die stocks have angles that don't match my dies & visa versa. Seems to me most of my dies have 2 dimples at the quadrants & the split is in between. Some dies have a cross bolt that sets the closure so ideally engaged as many dimples as possible with the set screws. I might be out to lunch on all this.

Attachments

Just a footnote on the quicky non-critical indexing. If you ever get into collets like 5C or ERxx, there are blocks available for speedy setups. For simple vise holding to machine 2,4,6 type facets they can be useful.

Attachments

I just checked my dies. They are TMX brand. The anti-rotation dimples are 180-deg apart 90-deg on either side of the die split in the middle. So that must have been my logic for drilling the die holder body with 4 set screws at 0,90,180,270 deg. Then I looked at my Asian tap wrench for this same size (1") OD die. It has set screws at 45-deg on either side of center, so like -45, 0, +45. As mentioned maybe there are different standards out there, but at best all I could do with this wrench is tag into one dimple. WTF.

One day I think I'm going to make my own conventional die wrench the same way I made the lathe version. The cast/stamped ones I have don't fit worth a crap & are crude. I'm sure I could come with something nicer & more functional. But I think the handles would have to be brazed or TIG welded to the die body. Might have to work out a deal with one of you welder types unless Santa brings me a TIG box instead of the usual sweater

One day I think I'm going to make my own conventional die wrench the same way I made the lathe version. The cast/stamped ones I have don't fit worth a crap & are crude. I'm sure I could come with something nicer & more functional. But I think the handles would have to be brazed or TIG welded to the die body. Might have to work out a deal with one of you welder types unless Santa brings me a TIG box instead of the usual sweater

DPittman

Ultra Member

Thanks for the helpful info Peter.similar to my pos

I will tell Santa that you've been good and deserve a tig for Christmas.

Another tip, point the end of your set screws, then even if you're off a little bit it doesn't really matter. (So long as the die sits in the holder with minimal clearance.)

--> Not very "machinist" of me, but I just eyeballed my set screw hole placement, and my holder works very well.

--> Not very "machinist" of me, but I just eyeballed my set screw hole placement, and my holder works very well.