Now that I have the concrete slab poured and the lathe bed pretty well positioned where I want it, I'm in the process of reassembly. In doing this I'm disassembling and cleaning a century worth of oil, grease, crud and paint from the sub assemblies. Oy the paint! I've counted so far at least three different colours, all slapped on with a brush including over things it shouldn't have been, like the lead screw and apron controls. The good thing is nothing was properly prepped so it basically flakes off with a scraper quite easily. But I digress.

The machine is a Fay and Scott 14x40 (give or take) metal lathe from, and I am guessing, the end of the 19th century.

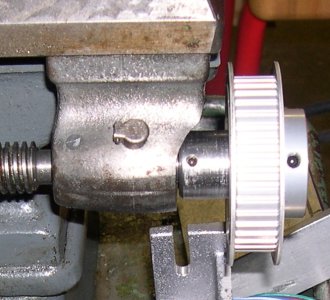

Disassembled the apron and realized the bevel gear for the clutch drive (key drive?) didn't look right. Copious de-greasing later and this is what I have.

Well I found some of those teeth, in the sliding drive gears.

As crazy as this may sound, this is the first actual damage and wear that I have found. Plenty of neglect but that has cleaned up quite well.

I've watched YouTube videos of the folks like Keith Rucker and David Richards repairing cast gears by brazing the broken areas and machinating the teeth back in. Those are spur gears though and usually larger. Also I don't have the tooling or know how at this point to actually do that. I'm thinking my options are:

- Braze it up like I see in the videos (it is a cast iron piece I believe) and then go at it with a a triangular file/needle files and rebuild the teeth that way

- Take it/send it to a machinist somewhere and have them re-machine it

- Troll EBay or other sites to see if I can find these pieces or a whole apron (HAHAHAHAHAHAHA! Right!)

- Bite the bullet and have a whole new set made up from scratch

I'm open to suggestions.

As an aside, trying to put this old lathe back in some semblance of working order has quite frankly nearly had me in tears more than once. Not the actual work, but the fact that this is very obviously a well made piece of machinery that was built and put together by people who also obviously took pride in their work. Then it was used, abused and neglected for years by people who didn't seem to give a shit. Makes me wonder what kind of work they turned out using it, and probably blamed the tool when it was crap.

The machine is a Fay and Scott 14x40 (give or take) metal lathe from, and I am guessing, the end of the 19th century.

Disassembled the apron and realized the bevel gear for the clutch drive (key drive?) didn't look right. Copious de-greasing later and this is what I have.

Well I found some of those teeth, in the sliding drive gears.

As crazy as this may sound, this is the first actual damage and wear that I have found. Plenty of neglect but that has cleaned up quite well.

I've watched YouTube videos of the folks like Keith Rucker and David Richards repairing cast gears by brazing the broken areas and machinating the teeth back in. Those are spur gears though and usually larger. Also I don't have the tooling or know how at this point to actually do that. I'm thinking my options are:

- Braze it up like I see in the videos (it is a cast iron piece I believe) and then go at it with a a triangular file/needle files and rebuild the teeth that way

- Take it/send it to a machinist somewhere and have them re-machine it

- Troll EBay or other sites to see if I can find these pieces or a whole apron (HAHAHAHAHAHAHA! Right!)

- Bite the bullet and have a whole new set made up from scratch

I'm open to suggestions.

As an aside, trying to put this old lathe back in some semblance of working order has quite frankly nearly had me in tears more than once. Not the actual work, but the fact that this is very obviously a well made piece of machinery that was built and put together by people who also obviously took pride in their work. Then it was used, abused and neglected for years by people who didn't seem to give a shit. Makes me wonder what kind of work they turned out using it, and probably blamed the tool when it was crap.