-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make a 5/16" bore with this boring bar?

- Thread starter eotrfish

- Start date

Former Member

Guest

If you purchased in store they should exchange it or give a refund. They should have an issue with it. If it was ordered and sent it might take a little longer.

I would just grind the profile of the right side to reduce the width to less than .300

eotrfish

Ultra Member

No - you're not missing anything. I had the same thought.Am I missing something ?

Heard back from KBC. They checked stock and all of the bars spec'd as 5/16" min. bore are oversize. Now they are checking their stock back east.

It's not a big deal since I found a miniature Chinesium 6mm boring bar in my stash - mission accomplished. It just pisses me off that the QC dept let this slip by.

I would just grind the profile of the right side to reduce the width to less than .300

I did grind the backside of one that I already had but it wasn't long enough to clear an upset on the part.

Chipper5783

Super User

Like John says, grind to get what you need. With that style BB you can expect to grind it. KBC was kind enough to give you a little extra material, and didn’t charge you for it.

Hopefully yours are an improvement of the import brazed boring cutters I had. It was many moons ago but the geometry was so messed up you could not even rotate the shank relative to boring head axis to get the proper cutting tool angle. I kept them just for occasional use in lathe tool post but even that was a clumsy setup without a flat reference on the shank. One of the YouTubers had a whole episode on 'remediating' them. But that's a dated generalization, maybe they are better now.

Borite has a line of cobalt cutters in nominal shank ODs which are pretty decent & I think you can get them individually from KBC.

Borite has a line of cobalt cutters in nominal shank ODs which are pretty decent & I think you can get them individually from KBC.

Attachments

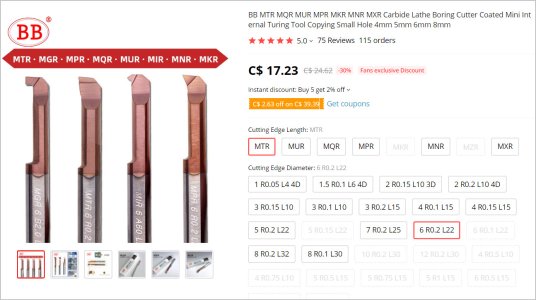

Somewhat related to small bores FWIW. I bought some of these carbide cutters form Ali along with a matching (6mm shank) tool holder. They cut really nice. So far used the straight boring & internal groove, the internal thread will be next. Good value compared to USA counterparts. I've only used these in lathe thus far but I don't see why an adapter couldn't be made for boring head socket.

Attachments

eotrfish

Ultra Member

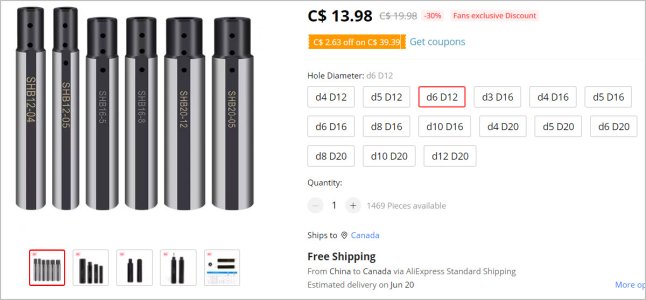

The oversize KBC bar was actually a blessing in disguise. It still was not long enough to clear the upset on the part so I had to go search in "other stuff" drawers. I found a 12mm x 6mm tool holder and boring bar that worked perfectly. I used the 12mm x 6mm tool holder directly in my boring head. Since the holder has two opposing flats it is plenty secure for boring 6061. I didn't bother shimming it to 1/2" dia.I don't see why an adapter couldn't be made for boring head socket

I have the tool holders in 4, 5, and 6mm with a selection of boring, grooving and trepanning tools. The internal grooving tool is sweet for 1mm cross section o-rings. I would highly recommend these Ali tools and holders for small precision work.