Tom Kitta

Ultra Member

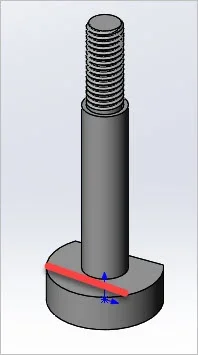

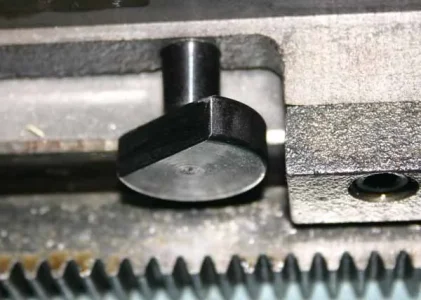

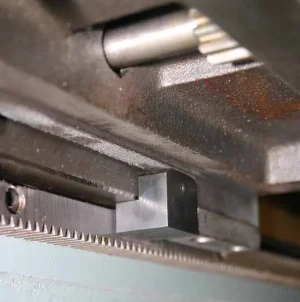

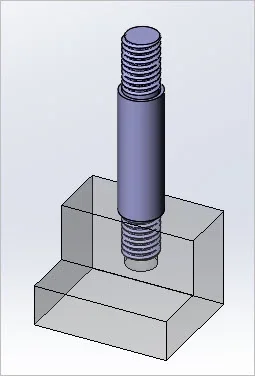

Here it is assembled in. But it does not tighten as I either have to add something to the "Green" area or I have to mill down a bit the area opposite to green.

So what should I do? Currently I think of adding a brass shim about 1mm thick to the green area.

What should I do? Other than this it fits perfectly. Original part was missing.

![IMG_20230522_141223[1].jpg](/data/attachments/42/42484-2294375d36b08c0b01e6171e0d12766e.jpg?hash=7AUuq9H5cw)