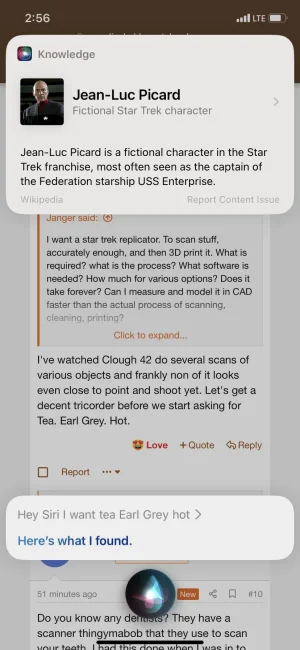

I want a star trek replicator. To scan stuff, accurately enough, and then 3D print it. What is required? what is the process? What software is needed? How much for various options? Does it take forever? Can I measure and model it in CAD faster than the actual process of scanning, cleaning, printing?

See this holder for hex shaped bits? I want more of them. How can I scan this with some sort of scanner? Then model it up and print it with a 3-D printer.? If I can do that then I have a 2023 version of a Star Trek replicator.

Somebody on the floor must be doing this. Tell us about your scanner in the process and how much the scanner will cost.

See this holder for hex shaped bits? I want more of them. How can I scan this with some sort of scanner? Then model it up and print it with a 3-D printer.? If I can do that then I have a 2023 version of a Star Trek replicator.

Somebody on the floor must be doing this. Tell us about your scanner in the process and how much the scanner will cost.

Attachments

Last edited: