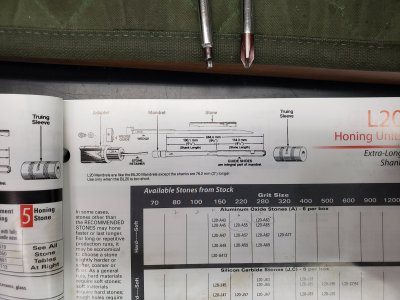

Many old shotgun barrels are pitted and in rough shape. Depending on how badly the bores are pitted, and depending on the wall thickness, you might use a series of reamers first, but then you need to hone the bores. I use a Sunnen portable Mandrel driver, powered by an old drill press head, mounted on its side, driven by a LEESON DC motor, attached to a section of heavy steel channel. Sitting atop a bench. Honing fluid is pumped from a tank inside the bench. The mandrels which hold the 4" stones are custom, because of the length I require. The stones are pushed upwards by a wedge which you manually advance by turning a wheel at the Sunnen driver. The mandrels come in many diameters specific for your needs, and the stones come in grits from around 100-900. Aluminum Oxide, Silicon Carbide, Diamond, or CBN.

Basically, select the proper mandrel size, choose the appropriate stone, true the stone. Put the mandrel into the shotgun barrel bore, put the honing oil spout into the muzzle. The stone/mandrel should be loose in the bore. Start pumping the honing fluid, start the drill press slowly using the foot pedal and start pushing the barrels in, and pulling out manually several times. Increase the pressure of the stones against the inside bore. Continue for some time, pushing/pulling, and rotating the barrels 90° every so often so that the weight of the stone/mandrel assembly isn't in just on one side. Stop, drain the barrels, clean them, inspect, and measure. Repeat until you get the desired finish by going to finer grit stones. This is not for the faint of heart, or those lacking upper body and hand grip strength!

Basically, select the proper mandrel size, choose the appropriate stone, true the stone. Put the mandrel into the shotgun barrel bore, put the honing oil spout into the muzzle. The stone/mandrel should be loose in the bore. Start pumping the honing fluid, start the drill press slowly using the foot pedal and start pushing the barrels in, and pulling out manually several times. Increase the pressure of the stones against the inside bore. Continue for some time, pushing/pulling, and rotating the barrels 90° every so often so that the weight of the stone/mandrel assembly isn't in just on one side. Stop, drain the barrels, clean them, inspect, and measure. Repeat until you get the desired finish by going to finer grit stones. This is not for the faint of heart, or those lacking upper body and hand grip strength!

Attachments

-

20220719_171131.jpg281.1 KB · Views: 12

20220719_171131.jpg281.1 KB · Views: 12 -

20220719_171202.jpg398.5 KB · Views: 12

20220719_171202.jpg398.5 KB · Views: 12 -

20220719_171216.jpg302.3 KB · Views: 12

20220719_171216.jpg302.3 KB · Views: 12 -

20220719_171301.jpg476.5 KB · Views: 12

20220719_171301.jpg476.5 KB · Views: 12 -

20220719_171511.jpg510.8 KB · Views: 12

20220719_171511.jpg510.8 KB · Views: 12 -

20220719_171520.jpg403.9 KB · Views: 12

20220719_171520.jpg403.9 KB · Views: 12 -

20220719_171709.jpg417 KB · Views: 11

20220719_171709.jpg417 KB · Views: 11 -

20220719_174519.jpg404.6 KB · Views: 11

20220719_174519.jpg404.6 KB · Views: 11 -

20220719_174621.jpg377.1 KB · Views: 12

20220719_174621.jpg377.1 KB · Views: 12