-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

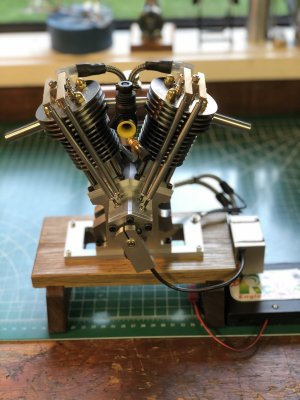

Hoglet V twin

- Thread starter Ken Mach

- Start date

There's a web site on that sort of stuff.

www.model-engine-ignition.com

www.model-engine-ignition.com

modelengineignition

A division of Outpost Enterprises, LTD Transistorized Ignition Modules, Simplified. We supply most everything you need for your model engine's ignition system. Complete systems around $50!

Hi Ken. Are you on HMEM? The engine gets discussed there.

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

Hoglet ignition

Gentlemen, I am currently building a Hoglet engine.I’ve built plenty of single engines but never a twin. I plan on using the Howell Tim- ignition kit that I’ve had great success with previously . My question is do I need 2 coils and their drivers or will one suffice? i would appreciate your...

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

Unfortunately I wont be much help. This outfit sells spark ignition modules, plugs, accessories... for multi-cylinder engines. More orientated to RC models though, so some cost premium for airborne components that have to be compact & low weight etc. And also USA based & I suspect spendy compared to some of the shop made solutions. Good luck. Hope to see a video when its running,

You can run what is called waste spark ignition. One sensor at TDC and one at the max advance point on the crankshaft. You fire both plugs if the engine is running an exhaust stroke at the same time as the compression stroke on the other cylinder. (Not all twins run symmetrically like that).

There are dual and quad ignition coils designed for that. Two spark plug high voltage outputs and a low voltage in.

You probably don't have to go with CDI like we did on this one.

John

There are dual and quad ignition coils designed for that. Two spark plug high voltage outputs and a low voltage in.

You probably don't have to go with CDI like we did on this one.

John

Ken, what ignition system do you have hooked up now? Is it giving problems or you are looking to change for some other reason?

Also, I'm interested in your carb. It looks like off an RC nitro vehicle? I discovered after I got some carb prospects for my radial that car carbs might be as good, if not better choice. Apparently some have inserts to vary venturi throat size? Is it a slide valve or rotating barrel?

Also, I'm interested in your carb. It looks like off an RC nitro vehicle? I discovered after I got some carb prospects for my radial that car carbs might be as good, if not better choice. Apparently some have inserts to vary venturi throat size? Is it a slide valve or rotating barrel?

The reason I ask is I was given a Craftsman Garden tractor with a 17.5HP B&S engine with a duff camshaft. Likely the carb needs a good going over too.Boring bar method I built it from drill rod

Long story short is the camshaft has centrifugal weight that releases compression when the cam is not turning quickly. That makes possible for the dinky starter and small battery to turn the engine over fast enough so when the weight flys out the compression happens and the engine fires.

The defective cam shaft surfaces as motor won't turn over. Hold rubber inner tube piece over carb inlet to prevent any air ingestion and engine hasn't got anything to compress so it turns over fast enough. Remove rubber flap and engine starts.

All the videos out there show the same issue. CAM is anywhere from $25 to real B&S for $150. Except B&S not available until end November. Far east clones often fail after several hours running. Not worth the effort to tear down and rebuild with unreliable CAM. So I've been thinking about making my own.

I have the tools...

Ken Mach

Member

I wouldn’t make a cam shaft for your engine from drill rod I’d look at 4140 htsr or something of that nature And it should be hardened and ground. Keep in mind that the Hoglet engine is not designed for long runs or to drive anything it’s a display engine basically.The reason I ask is I was given a Craftsman Garden tractor with a 17.5HP B&S engine with a duff camshaft. Likely the carb needs a good going over too.

Long story short is the camshaft has centrifugal weight that releases compression when the cam is not turning quickly. That makes possible for the dinky starter and small battery to turn the engine over fast enough so when the weight flys out the compression happens and the engine fires.

The defective cam shaft surfaces as motor won't turn over. Hold rubber inner tube piece over carb inlet to prevent any air ingestion and engine hasn't got anything to compress so it turns over fast enough. Remove rubber flap and engine starts.

All the videos out there show the same issue. CAM is anywhere from $25 to real B&S for $150. Except B&S not available until end November. Far east clones often fail after several hours running. Not worth the effort to tear down and rebuild with unreliable CAM. So I've been thinking about making my own.

I have the tools...

Ken Mach

Member

It’s an ignition designed for model aircraft engine an Excel …..it will fire with a strong magnet but this Engine will only allow for a very small magnet not strong enough to trip the hall sensor. I tried a combination of different magnets and hall sensors with no luck, i parked the engine about a year ago out of frustration but it’s time to tackle the problem and finish the project.Ken, what ignition system do you have hooked up now? Is it giving problems or you are looking to change for some other reason?

Also, I'm interested in your carb. It looks like off an RC nitro vehicle? I discovered after I got some carb prospects for my radial that car carbs might be as good, if not better choice. Apparently some have inserts to vary venturi throat size? Is it a slide valve or rotating barrel?

The carb is an RC carb as well I bought it on Amazon sorry I can’t remember the details but I believe it has a .250 bore larger ones

were available when I was looking.

Lee Valley Tools has some small very powerful magnets. I've been able to trip a hall sensor with those.It’s an ignition designed for model aircraft engine an Excel …..it will fire with a strong magnet but this Engine will only allow for a very small magnet not strong enough to trip the hall sensor. I tried a combination of different magnets and hall sensors with no luck

Ken Mach

Member

Boring bar method I built it from drill rod

Boring bar method I built it from drill rod

I’ll take a look ….thanksLee Valley Tools has some small very powerful magnets. I've been able to trip a hall sensor with those.

You have to watch out for magnet polarity as in the sensor is only sensitive to either North or South. The side of the sensor is also critical for best operation.

This is how mine is mounted inside the 3D printed holder with the pull up resistor and LED to show activation. I filled that with void epoxy to keep the wires in the right place.

Here is the sensor tripping as the magnet rotates around.

And you can see here there is plenty of space to the sensor and the magnet is not that big.

I believe the one I'm using is the

Item 99K3101, 1/4" × 1/10" Rare-Earth Magnet

www.leevalley.com

www.leevalley.com

This is how mine is mounted inside the 3D printed holder with the pull up resistor and LED to show activation. I filled that with void epoxy to keep the wires in the right place.

Here is the sensor tripping as the magnet rotates around.

And you can see here there is plenty of space to the sensor and the magnet is not that big.

I believe the one I'm using is the

Item 99K3101, 1/4" × 1/10" Rare-Earth Magnet