Nice fix Shawn, just curious what component you replaced? It has become rarer and rarer to find something you can actually solder without a microscope. The cart looks great too even a spot for the tank. I was lucky with my Lincoln mig 140 as well as a local farmer put it up on kijiji for free said it didn't work so it was super close like 10k away so I went right away he didn't think there was much hope for it, I took it home gave it going over and tightened a few connections and have been using it ever since there was only one time it acted a bit weird but could have been a bad ground but its welded everything I have asked.

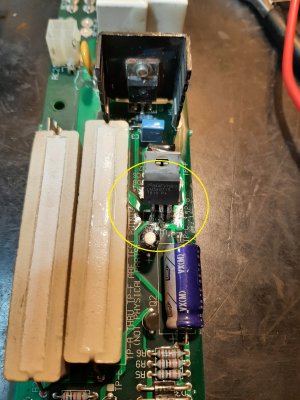

The component is an LM340T Voltage regulator. The photo is before I worked on it. It actually, may have been ok. I don't know the history but in an attempt to repair the drive roller problem, U1 was removed I think but the board was damaged in the process. Then when replaced, I don't think connections were completed. I just pulled it out, and replaced it since I had one. The damaged traces might have been the problem this time. My replacement is not pretty because I had to be able to solder from the top and the bottom due to board damage. It would be tail light warranty repair. ...

I wanted to try it out so put the grab hooks on the tractor bucket with it today. Seemed to work fine. Flux core.

,

Nice find on the Mig 140. I had the weldpak 100 for a while, and then sold it when I got some other machines but no other 120 Volt unit. I then came across one when I bought some other stuff and got it again. Handy to have. I keep it at camp. Used it last summer to help a neighbour out with putting fenders back onto his trailer after a rough fishing trip. The trailer could not be hauled far without ripping tires apart so being able to fix it just down the road was great!

Your lucky I bought a Millermatic 135 for $50. that turn out to release the magic smoke from a capacitor (1 of 6) and replaced them all for around $250. The new ones were for the next size up welder and was told it should run a bit smoother with them.

That sucks....but as you probably reasoned, you upgraded the unit and still have a good little welder for $300. Maybe not the stellar deal you hoped for, but still a fair price if in otherwise good condition. Did you replace anything else or just the caps? In my experience, usually something takes out a cap like that, ie, a shorted semiconductor. But when the caps get old, the electrolyte dries up, gradually changing the value and specs, so swapping all was a good preventative measure. If it has been good since, you should be good.

I have worked on a few of the small size welders like that. ( not a millermatic though, I don't think) Many use several button diodes connected between two plates. Occasionally, I have found one or two shorted where the others (4 or 5) tested ok. I learned to just replace all of them if one goes. In parallel, if one fails open, the others are carrying extra load, till one more fails, then if the unit is still working 4 of 6 are now carrying the load. They all get stressed more as each fails, if they fail open. If they fail closed of course, the circuit breaker lets us know. ...

Welders are fun to work on...but then I like welders and I like electronics so nice projects for a nerd like me.....

A side story, when I was in the seller's shop, I noted he had a DRO on his milling machine. I commented on it and he said he had ripped the cable out of the x axis scale. I offered to look at it for him. He was able to send me photos of the inside of his other ones and I was able to clean up the board and repair the connections. Took it back today and he was tickled pink when we hooked it up and he was back in business!

So the guy sells me a defective welder and gets a free scale fix out of it! I am not a good horse trader....probably not a good business person....

but I think I have a favour in the bank.

Cheers,