What would your preference on a hinge be?

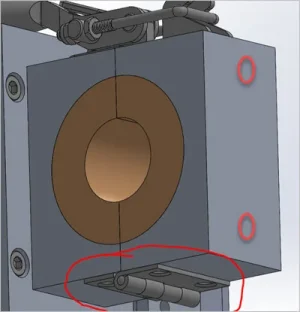

Assemblies like that are only as strong as their weakest link. In this case, you have a closing clamp and a hinge that are miniscule compared to the block. In the surface of it, that seems to be a bit of a contradiction.

If I were you, I'd start by asking myself if I really needed a clamp block that big.

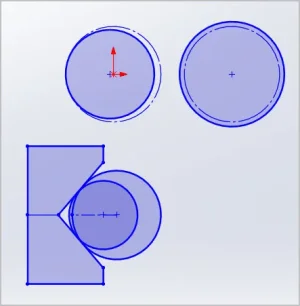

If so, then I'd abandon an external hinge and lock and I'd machine them both right into the block with hinge fingers and lock pin diameters in the range of 1/3 the cross sectional area. Think mitred halves with a hinge pin. If I understand your application, I don't think the fit is all that critical so it's an easy milling operation to make the mitres and any play could be taken up with thin plastic washers to align the halves. Drill for the pins after the hinge mitres are finished so everything lines up perfectly.

If not, I'd abandon the entire block and modify a typical door hinge to serve as both the hinge and the block. Door hinges are available in a very wide range of sizes and types. Most are easily bent and many can be modified (machined, cut, welded, etc) to serve as both ends of your clamp.

If you want a quicker solution, you can also make or buy huge hinges for barn doors, safe doors, cold room doors, etc that could be cut down to fit your block with a strength similar to the block.

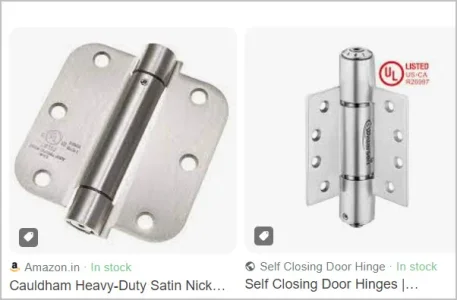

Or, here are some quick buy heavy duty hinges that are prolly more like you had in mind.

Atibin 3 Screw Heavy Duty Stainless Marine Door Hinges

https://a.co/d/d1zlKKA

Atibin 2 Screw Heavy Duty Stainless Marine Door Hinges

https://a.co/d/20CA3Ca

A Google search for Heavy Duty Hinges turns up a million other options. In your case, I think a pair of thick steel hinges might be all you need.

But as

@Dabbler said, it all depends on the loads you expect to encounter.