@Mcgyver cover your eyes & don't judge me! Haha. I'm back on my tool cutter grinder 'kit', making improvements, machining new parts. There are so many things that need attention its hard to know where to start, but I'm committed now. I'll document it better once I get some time, but thought I'd throw this out.

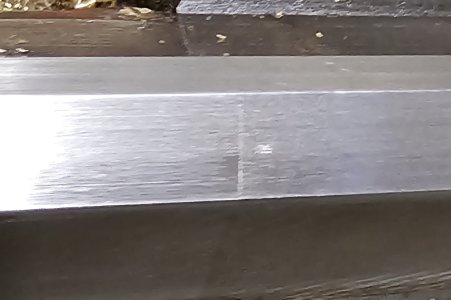

This dovetail block holds the indexing head on top & traverses laterally on a leadscrew which I've re-made. I'm drawing up new gib strips because the stock ones are so pathetic & what I assumed were contributing to the poor fit & jammy motion. But once I removed them altogether I could detect the block itself was rocking on the underlying (reasonably flat) casting surface. Turns out the 2 horizontal dovetail surfaces, which should be coplanar, are about 0.015" different elevation & the high one is tilted. For some reason they decided to fully harden this block, which I don't understand. Its like a piece of glass, a file wont touch it. Maybe it warped in the quench but even that seems doubtful. It has some other ugly machining & dimensional issues so I considered re-making it altogether. But that's a bit of work too. So I figured, try & salvage it.

I felt penned the face & just started going at it with my Dremel stone, trying for equal-ish material removal. Then dress the face with a diamond file & flat stone with oil, rinse & repeat. Its actually hard to do much damage with the Dremel because the material is so hard. About 15 cycles later its getting close dimensionally & the hill worked out. This thing only moves +/-10mm & gets parked into position, so as long as its reasonably smooth & doesn't buzz under power. Now the other surface looks ugly by comparison, but I'll deal with that later. Hopefully the gib retrofit will helps things a bit more. The battle continues.

So this 'Dremel Scraping' could be a big thing. I'm thinking... YouTube videos, international classes, sponsorhip, books, podcasts, my own line of stones, T-shirts, special swag.... HaHa

Sorry I'm too busy to take orders on your lathe bed until I hire some staff.

This dovetail block holds the indexing head on top & traverses laterally on a leadscrew which I've re-made. I'm drawing up new gib strips because the stock ones are so pathetic & what I assumed were contributing to the poor fit & jammy motion. But once I removed them altogether I could detect the block itself was rocking on the underlying (reasonably flat) casting surface. Turns out the 2 horizontal dovetail surfaces, which should be coplanar, are about 0.015" different elevation & the high one is tilted. For some reason they decided to fully harden this block, which I don't understand. Its like a piece of glass, a file wont touch it. Maybe it warped in the quench but even that seems doubtful. It has some other ugly machining & dimensional issues so I considered re-making it altogether. But that's a bit of work too. So I figured, try & salvage it.

I felt penned the face & just started going at it with my Dremel stone, trying for equal-ish material removal. Then dress the face with a diamond file & flat stone with oil, rinse & repeat. Its actually hard to do much damage with the Dremel because the material is so hard. About 15 cycles later its getting close dimensionally & the hill worked out. This thing only moves +/-10mm & gets parked into position, so as long as its reasonably smooth & doesn't buzz under power. Now the other surface looks ugly by comparison, but I'll deal with that later. Hopefully the gib retrofit will helps things a bit more. The battle continues.

So this 'Dremel Scraping' could be a big thing. I'm thinking... YouTube videos, international classes, sponsorhip, books, podcasts, my own line of stones, T-shirts, special swag.... HaHa

Sorry I'm too busy to take orders on your lathe bed until I hire some staff.