I recently found out that I'm not the only person with Hercus machine tools on here so I thought it best to start a thread about it here.

I have a Hercus lathe and a milling machine. The mill was my start in CNC. I got it running with Mach 3 and being new to CNC found it to be way to limited in it's travels. Way to easy to overtravel and hit a stop. Beginner errors. I also had trouble with Mach 3 doing full rapid axis runaways. I ordered a bigger mill shortly after. When I finish with the lathe the mill will get a Centroid Acorn. I converted my bigger milling machine to an acorn and could not be happier with it. It just chugs along and never makes and mistakes that I didn't create on my own.

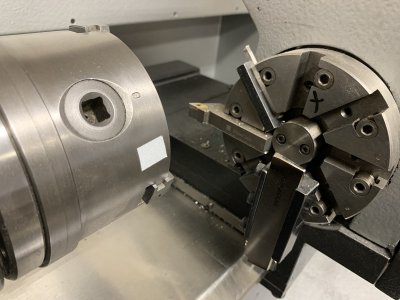

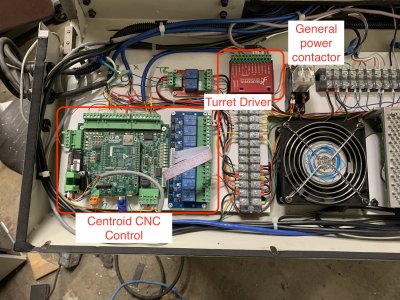

The lathe started out with a Mach 3 conversion that is now undergoing a conversion to a Centroid Acorn. Same reasons as with the mill. If anyone is considering upgrading to an acorn I do have some advice. Get everything working before you tackle the turret. I paid Centroid to update the PLC and unfortunately when you update the software you have to manually update the PLC or pay Centroid to do it. The turret is non-standard so that is why you need to manually edit the PLC. Next time I get them to edit it I will tell them to use a different colour text for the edits so I can do the entire update myself. The lathe has an air chuck and 2 turrets.

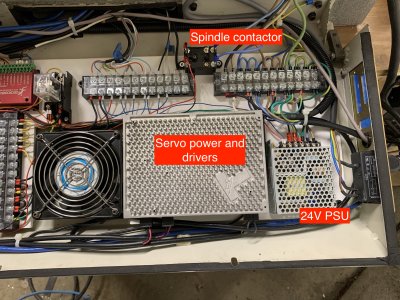

During the conversion to Mach 3 and the Acorn I used the original servos. Close enough to be adaptable versions of the original servos are available on Ebay.The resolvers were removed and replaced with AMT-102 encoders. It's likely these will not be totally successful and be replaced by a better quality encoder.

I'll post photos in the future. The machine is partially disassembled for the control update, so not presentable.

I have a Hercus lathe and a milling machine. The mill was my start in CNC. I got it running with Mach 3 and being new to CNC found it to be way to limited in it's travels. Way to easy to overtravel and hit a stop. Beginner errors. I also had trouble with Mach 3 doing full rapid axis runaways. I ordered a bigger mill shortly after. When I finish with the lathe the mill will get a Centroid Acorn. I converted my bigger milling machine to an acorn and could not be happier with it. It just chugs along and never makes and mistakes that I didn't create on my own.

The lathe started out with a Mach 3 conversion that is now undergoing a conversion to a Centroid Acorn. Same reasons as with the mill. If anyone is considering upgrading to an acorn I do have some advice. Get everything working before you tackle the turret. I paid Centroid to update the PLC and unfortunately when you update the software you have to manually update the PLC or pay Centroid to do it. The turret is non-standard so that is why you need to manually edit the PLC. Next time I get them to edit it I will tell them to use a different colour text for the edits so I can do the entire update myself. The lathe has an air chuck and 2 turrets.

During the conversion to Mach 3 and the Acorn I used the original servos. Close enough to be adaptable versions of the original servos are available on Ebay.The resolvers were removed and replaced with AMT-102 encoders. It's likely these will not be totally successful and be replaced by a better quality encoder.

I'll post photos in the future. The machine is partially disassembled for the control update, so not presentable.