swunderlick

Member

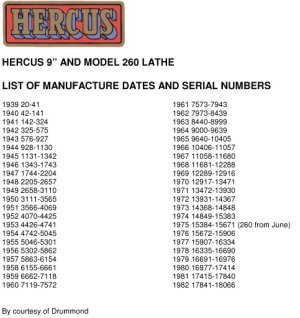

Not too long ago I picked up an old Hercus 260 ATM, this will be the first machine that I have personally owned.

And as things typically go for me I very quickly found something wrong that I wanted to fix. In this case it was just a worn out half nut. So I pulled the apron off and started to see more and more wear and tear on the parts. And now my "new" machine looks like this. In reality this is well into the project, it was extremely filthy and neglected so most parts shown here have been through the first round of cleaning just enough that I could identify the most critically worn components and get them on order. Now comes the real deep clean and reassembly.

This really wasn't part of the plan, I just want to start turning something.

And as things typically go for me I very quickly found something wrong that I wanted to fix. In this case it was just a worn out half nut. So I pulled the apron off and started to see more and more wear and tear on the parts. And now my "new" machine looks like this. In reality this is well into the project, it was extremely filthy and neglected so most parts shown here have been through the first round of cleaning just enough that I could identify the most critically worn components and get them on order. Now comes the real deep clean and reassembly.

This really wasn't part of the plan, I just want to start turning something.