DPittman

Ultra Member

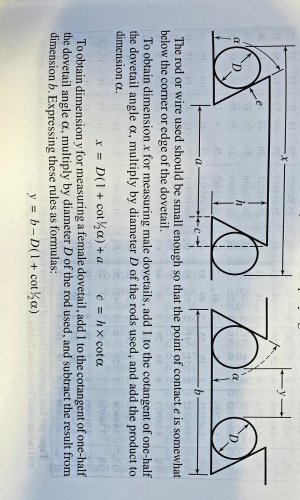

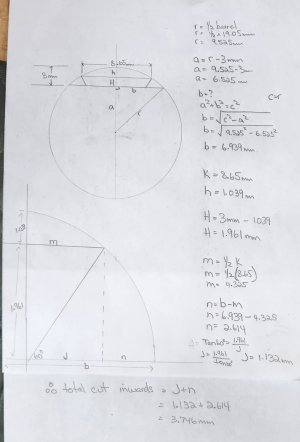

I'm wanting to cut some 60 degree dovetail grooves in an air rifle barrel to accept a front site. I'm having trouble with figuring out the math in order to cut them correctly. Maybe my childish drawing might help to convey what I'm trying to achieve.

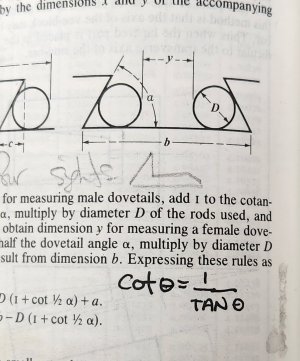

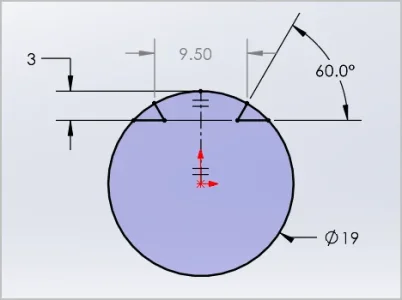

I think I have to use the cosign of 30 degrees to determine the travel of the cutter inwards to achieve the proper distance of the top of the groove which is indicated in the picture as 8.65mm.

If I move the cutter down 3mm from the top of the barrel down to achieve the correct distance for the bottom of the groove, how do I determine the inward movement to achieve the 8.65mm distance between the two grooves?

I think I have to use the cosign of 30 degrees to determine the travel of the cutter inwards to achieve the proper distance of the top of the groove which is indicated in the picture as 8.65mm.

If I move the cutter down 3mm from the top of the barrel down to achieve the correct distance for the bottom of the groove, how do I determine the inward movement to achieve the 8.65mm distance between the two grooves?