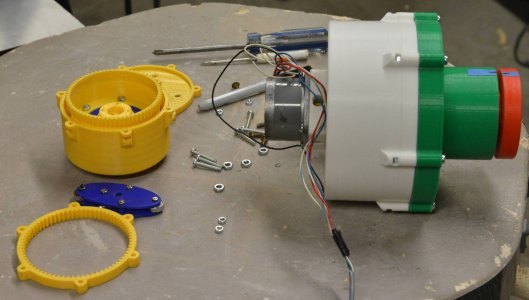

This has been an ongoing project for the last month or so and I thought I'd share some of the results. I got into it while waiting for parts for my power drawbar project. Now I have a harmonic drive for my 4th axis and one day (hopefully soon) I will cast the pattern so I can use it. It's already connected to LinuxCNC as the 4th axis. Just doesn't do anything.

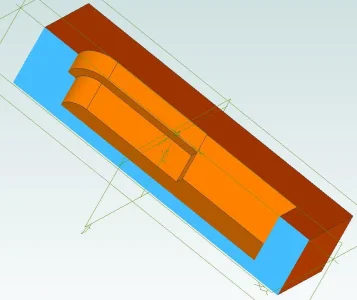

So this harmonic drive video set me in the direction to print my own. I have a metal working friend who decided he too wanted to make one. His is now being 'exercised'. I was missing some of the bearings so I kludged the wave generator with just a double set. He found bearings and used the full 10 bearing plate. He also redesigned the cup to be more flexible.

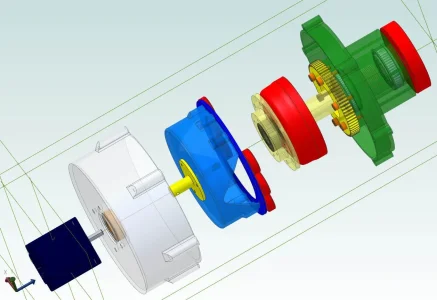

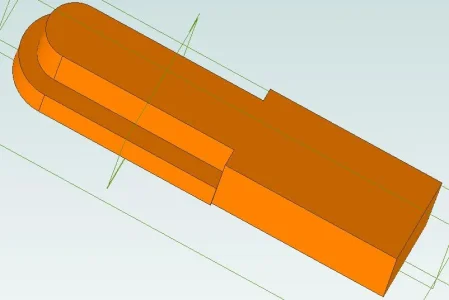

Meanwhile I found a paper by some Chinese PhDs on an alternative harmonic drive named HGD_EWG so I designed one using the two gear teeth parts from the first. It provides 36:1 and is quite large. Still needs some work. Instead of the wave generator on the inside it's now on the outside.

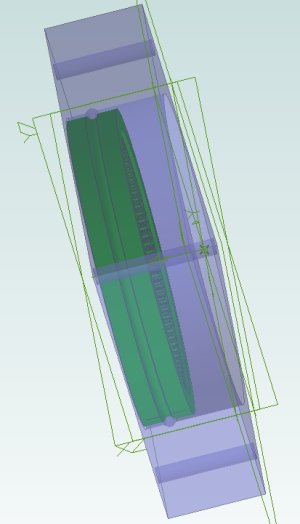

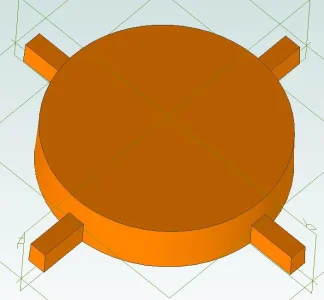

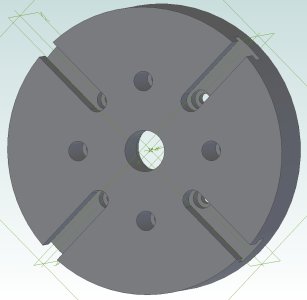

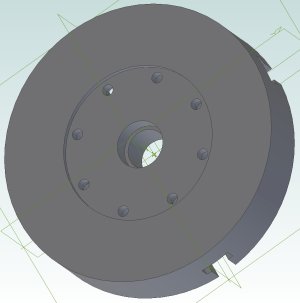

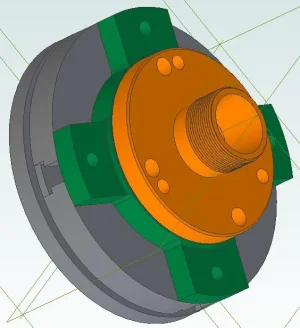

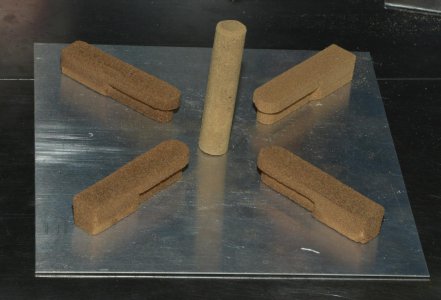

I am now distracted with a dual planetary (theoretically also zero backlash) system. It still needs mounting and a motor attached so it's still totally in an experimental stage. The initial drawings were done by Todd Zuercher on the LinuxCNC group in FreeCAD 0.19. I exported them as STEP files into Alibre and then took it from there to make 3D prints of his design. After some 'issues' we've come up with something that appears to work. Big thing about this is it uses standard involute gear profile and as long as one can make the inner ring gear there is no wearing out of a flex cup like a harmonic.

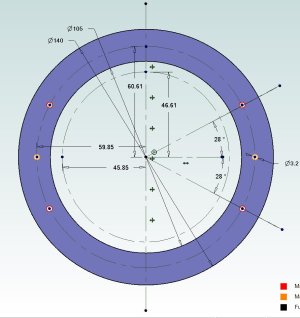

This one is designed with 1.25 module teeth and has 100:40 and 101:41 values for 67:1. The outer ring is 150mm in diameter.

Needless to say the 3D printer has been busy as has the lathe boring out bearing holes for close fits.

So this harmonic drive video set me in the direction to print my own. I have a metal working friend who decided he too wanted to make one. His is now being 'exercised'. I was missing some of the bearings so I kludged the wave generator with just a double set. He found bearings and used the full 10 bearing plate. He also redesigned the cup to be more flexible.

Meanwhile I found a paper by some Chinese PhDs on an alternative harmonic drive named HGD_EWG so I designed one using the two gear teeth parts from the first. It provides 36:1 and is quite large. Still needs some work. Instead of the wave generator on the inside it's now on the outside.

I am now distracted with a dual planetary (theoretically also zero backlash) system. It still needs mounting and a motor attached so it's still totally in an experimental stage. The initial drawings were done by Todd Zuercher on the LinuxCNC group in FreeCAD 0.19. I exported them as STEP files into Alibre and then took it from there to make 3D prints of his design. After some 'issues' we've come up with something that appears to work. Big thing about this is it uses standard involute gear profile and as long as one can make the inner ring gear there is no wearing out of a flex cup like a harmonic.

This one is designed with 1.25 module teeth and has 100:40 and 101:41 values for 67:1. The outer ring is 150mm in diameter.

Needless to say the 3D printer has been busy as has the lathe boring out bearing holes for close fits.