I was googling and googling on how to use the HAAS CNC Mill to manually mill something. ie use the MPG hand wheel to move an axis back and forth to just do some silly little thing like true up the end of stock or drill 1 hole. I want to do this because to use the mill I know of 3 ways to operate it yet they are all slow to setup. I just could not find anything relevant on how to operate the machine without writing or generating gcode, and I finally figured it out last night while discussing it with Dabbler. This is how CNC is less productive than manual machining for small jobs. Normally you have to generate that GCODE somehow. Here are the three (now 4) main ways I know of to operate the machine:

1. Manually write GCode by hand. Yes you can do this but it's easy to make mistakes and for heaven's sakes HAAS why can't I plug in a normal keyboard? There is a USB port! I touch type so a normal keyboard is miles faster. Any hand written keyboard gcode needs to be verified - carefully and suspiciously examined as it runs. Don't crash! You probably should to do a dry run above the part. So it's slow to use. It is just like writing & debugging a software program but there is no UNDO and bugs could result in real life crashes.

2. Use the HAAS CNC built in wizards to generate GCode. I do this and it's quicker than writing gcode by hand usually but still there are often 10 or 20 parameters to think about and set. It's easy to to get one wrong and you still need to carefully execute the program. Some things you think should be easy are missing from the wizards. Like a simple side milling wizard (curious oversight).

3. CAD/CAM. Design the part in Fusion 360, switch to CAM mode, build the stock model and then setup all the required milling tooling & operations, Simulate the job to look for problems. Then generate the gcode file and move it to the machine over wifi. With method 3 it is an hour at least for me anyway. Probably a day on a harder part and then a bunch of rework while I get the bugs out and repost. It's the fastest way to make a second part or 1+X number of parts but the first part is slow to produce.

4. Use the jog mode and manually move the table and spindle using the MPG wheel. Trouble I've been having is turning on the spindle while in JOG mode. It seems I need one line of gcode to get it started. The code turn on and set the spindle RPM:

M03 S1200; <- turn on the spindle to 1200rpm

Here I am assuming there is a tool in the spindle, the coordinate system is set (say G54), and all other modal commands are off.

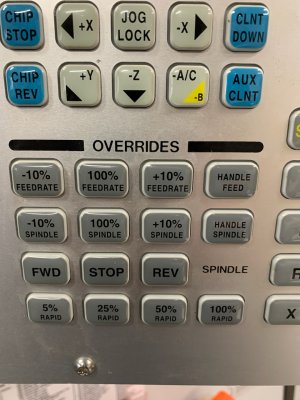

This program turns on the spindle. To use put it in single step mode, press cycle start and the spindle turns on. Now you can use JOG to move the axis AND start the spindle with the FWD STOP REV buttons. (The doors have to be shut). Without the GCode M03 S1200 the spindle won't turn on - I guess because the machine does not know what speed to run the spindle. So this could be handy for example to square up some stock or drill a hole. Like on a manual mill I have to turn the MPG wheel through all the required operations so there is no walking away while the mill works. But hey no programming and there is DRO read out for positioning.

Anybody else using manual operations like this to manually make parts on their CNC? And does anyone else have another way than these 4?

1. Manually write GCode by hand. Yes you can do this but it's easy to make mistakes and for heaven's sakes HAAS why can't I plug in a normal keyboard? There is a USB port! I touch type so a normal keyboard is miles faster. Any hand written keyboard gcode needs to be verified - carefully and suspiciously examined as it runs. Don't crash! You probably should to do a dry run above the part. So it's slow to use. It is just like writing & debugging a software program but there is no UNDO and bugs could result in real life crashes.

2. Use the HAAS CNC built in wizards to generate GCode. I do this and it's quicker than writing gcode by hand usually but still there are often 10 or 20 parameters to think about and set. It's easy to to get one wrong and you still need to carefully execute the program. Some things you think should be easy are missing from the wizards. Like a simple side milling wizard (curious oversight).

3. CAD/CAM. Design the part in Fusion 360, switch to CAM mode, build the stock model and then setup all the required milling tooling & operations, Simulate the job to look for problems. Then generate the gcode file and move it to the machine over wifi. With method 3 it is an hour at least for me anyway. Probably a day on a harder part and then a bunch of rework while I get the bugs out and repost. It's the fastest way to make a second part or 1+X number of parts but the first part is slow to produce.

4. Use the jog mode and manually move the table and spindle using the MPG wheel. Trouble I've been having is turning on the spindle while in JOG mode. It seems I need one line of gcode to get it started. The code turn on and set the spindle RPM:

M03 S1200; <- turn on the spindle to 1200rpm

Here I am assuming there is a tool in the spindle, the coordinate system is set (say G54), and all other modal commands are off.

This program turns on the spindle. To use put it in single step mode, press cycle start and the spindle turns on. Now you can use JOG to move the axis AND start the spindle with the FWD STOP REV buttons. (The doors have to be shut). Without the GCode M03 S1200 the spindle won't turn on - I guess because the machine does not know what speed to run the spindle. So this could be handy for example to square up some stock or drill a hole. Like on a manual mill I have to turn the MPG wheel through all the required operations so there is no walking away while the mill works. But hey no programming and there is DRO read out for positioning.

Anybody else using manual operations like this to manually make parts on their CNC? And does anyone else have another way than these 4?

Last edited: