pdentrem

Well-Known Member

This has been idling for a very long long time.

Rolling mill rolls are ground flat but when heated they expand but not equally across the working length, as the heaters are usually in the center and the end which are near the oil cooled bearings are naturally cooler. So naturally the material rolled is slightly thinner in the center by a few tenthousandths. In the past we tried using CNC grinding but total failure and reground the rolls back to flat. The next attempt was to use a large diamond wet stone and basically flattened the center. This worked but what a job!

I had designed a power grinder to do this quicker but management was lukewarm. Finally a couple months ago, we were given the go ahead to build it.

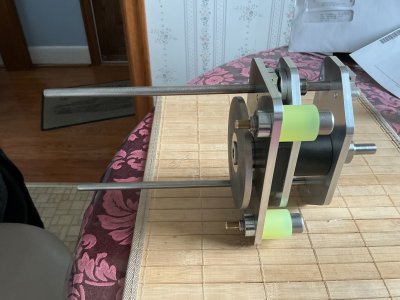

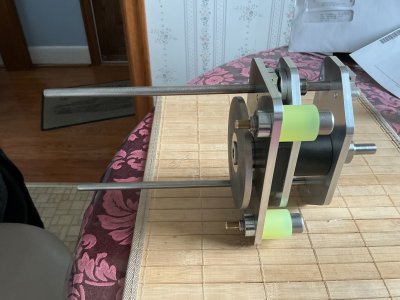

Per the photos the two long rods sit the grinder on the top of the roll and the two brass faced (still need to trim the brass) will register and the wheel will slightly contact the rolls and remove a couple thousandths. We only need the 2-3” of the center done and the rolls are 6” across. The wheel is 400 diamond grit and 4” in diameter.

Hopefully the photos are semi coherent!

Pierre

Rolling mill rolls are ground flat but when heated they expand but not equally across the working length, as the heaters are usually in the center and the end which are near the oil cooled bearings are naturally cooler. So naturally the material rolled is slightly thinner in the center by a few tenthousandths. In the past we tried using CNC grinding but total failure and reground the rolls back to flat. The next attempt was to use a large diamond wet stone and basically flattened the center. This worked but what a job!

I had designed a power grinder to do this quicker but management was lukewarm. Finally a couple months ago, we were given the go ahead to build it.

Per the photos the two long rods sit the grinder on the top of the roll and the two brass faced (still need to trim the brass) will register and the wheel will slightly contact the rolls and remove a couple thousandths. We only need the 2-3” of the center done and the rolls are 6” across. The wheel is 400 diamond grit and 4” in diameter.

Hopefully the photos are semi coherent!

Pierre