-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grind lathe bed in ontario

- Thread starter 05plsrt4

- Start date

Sorry can't help with that.

But I noticed that you are in London which is only an hour from me. So I wanted to take this opportunity to welcome you to the forum and invite you to reach out for help when you need it.

Consider putting a post in the new member introductions section and telling others a bit more about yourself.

But I noticed that you are in London which is only an hour from me. So I wanted to take this opportunity to welcome you to the forum and invite you to reach out for help when you need it.

Consider putting a post in the new member introductions section and telling others a bit more about yourself.

trlvn

Ultra Member

I have no idea if any of these will even talk to you. Please let us know how it goes.

The 'conventional wisdom' is that re-grinding a lathe bed (and then adjusting the fit of all mating parts) is so expensive as to be impractical. And that few shops with the equipment and experience necessary to do a good job are even willing to quote on the work since it is a relatively complex one-off job that keeps them from doing more profitable work. But maybe the conventional wisdom is wrong?

What lathe are you looking to regrind?

Craig

surface grinding in ontario - Bing

Intelligent search from Bing makes it easier to quickly find what you’re looking for and rewards you.

I'm interested in what comes out in this thread. There was a chap in Kingston and another near KW iirc, but that was awhile ago. Both were job shops envirionments that were happy to grind lathe beds, hobbyist or otherwise. The grinding wasn't ever cheap, 1500 last time I priced it, but not prohibitive considering you are working toward a lathe that will be as new. Maybe that has doubled now.

I don't disagree with that statement; however on a small lathe the fitting, scraping everything into alignment, is by far the lions share of the cost/labour and is usually done as a labour of love by its owner. I would say if you had the money for that, you'd probably be better to buy the lowest mileage, best shape 10ee or HLV that was out there.

My advice is just make sure the lathe is worthy, its a lot of money, time and brain damage to recondition a machine. Well worth it, but only if you end up with a something absolutely obrt the top fantastic. just imo.

The 'conventional wisdom' is that re-grinding a lathe bed (and then adjusting the fit of all mating parts) is so expensive as to be impractical

I don't disagree with that statement; however on a small lathe the fitting, scraping everything into alignment, is by far the lions share of the cost/labour and is usually done as a labour of love by its owner. I would say if you had the money for that, you'd probably be better to buy the lowest mileage, best shape 10ee or HLV that was out there.

My advice is just make sure the lathe is worthy, its a lot of money, time and brain damage to recondition a machine. Well worth it, but only if you end up with a something absolutely obrt the top fantastic. just imo.

Last edited:

The cost to hand scrape a machine tool, particularly a lathe is as much as having it ground... because you need to acquire tools you likely dont have. The good thing is that you can sell straight edges once you no longer need them

I have hand scraped a few beds, but grinding is the imo the only reasonable option if its a hardened bed. The late Harry Beckley (a very talented man who chronicled some reconditioning projects on PM, search for the "the wreck") scraped a hardened 10ee bed, which still astounds me. He's got a gold man club card. when i've tried a carbide scraper, it barely mars the surface.

Even if not hardened, outsourcing is still an appealing option if you take into account your time. I used to do things to in part to prove I could or because I could to save a buck....more often now I just want to get on with it.

Last edited:

Dabbler

ersatz engineer

Ask Modern tool. If you give them just the bed, so no disassembly/assembly is required. That is the expensive part. The shipping and grinding will cost a lot less than them putting Tercite on your apron/saddle and scraping it in to fit.

If you are skilled, these things are easy for you. If you are not, only very rare or valuable lathes are a candidate.

If you are skilled, these things are easy for you. If you are not, only very rare or valuable lathes are a candidate.

Former Member

Guest

I'm going to interject something here, grinders are not the only option depending how big the lathe is.

SHAPER anyone????

The second is depending on the side, hand sanding provided you have a stable and long enough enough base to sand with.

This can get you very close with a little effort.

Again depends how much you need to remove and what you are trying to achieve.

Here was the example that comes to mind of sanding, even though its a head.

SHAPER anyone????

The second is depending on the side, hand sanding provided you have a stable and long enough enough base to sand with.

This can get you very close with a little effort.

Again depends how much you need to remove and what you are trying to achieve.

Here was the example that comes to mind of sanding, even though its a head.

Last edited:

ThirtyOneDriver

Johnathan (John)

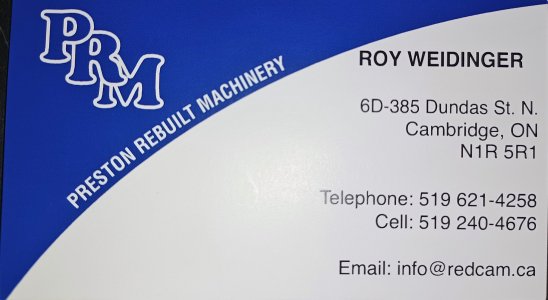

I looked them up - they're just down the street from me and on the opposite side of the train tracks from my metal supplier.Preston Rebuilt Machinery Industries.

385 Dun Street

Cambridge, ON,

519-653-2306

Having only driven by and not having stopped in, the building's appearance fits the stereotype of an old, large, industrial/fabrication/machining shop.

They're actually on Dundas St.

Update: Based on Street View, I don't think they're there anymore. I'll actually take a drive by this morning and check.

Attachments

ThirtyOneDriver

Johnathan (John)

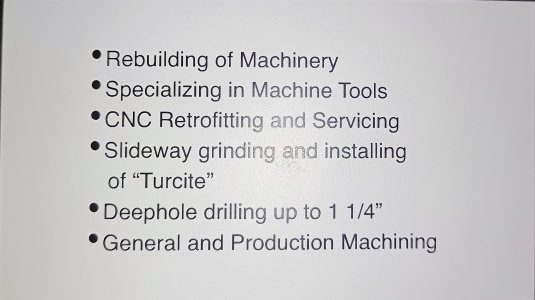

So I was pleasantly surprised to see a small sign hanging on a fence indicating that Preston Rebuilt Machinery was located in unit 6D and stopped in to their shop. Linda was there but Roy was on a service call (seems like a one man gig) and gave me a quick tour and a business card. She explained that their main focus is rebuilding machines (there was a disassembled mill similar to what I perceive when someone says Bridgeport) and gave me some details that went well over my head.

Best way to contact them is by e-mail and if there's going to be questions regarding your machine/quoting that pictures be included.

Pics of their card are attached.

Best way to contact them is by e-mail and if there's going to be questions regarding your machine/quoting that pictures be included.

Pics of their card are attached.

Attachments

ThirtyOneDriver

Johnathan (John)

Yeah... Red/Cam Man. would be in the same complex so that would have made things easier (I don't leave my place often), but it's so close that I can integrate a visit w/ my next set of errands @TorontoBuilder.

Former Member

Guest

There are a few other videos online very clearly showing the advantages of shapers along with why they have sort of fallen off the radar of most machinist (unfortunately). Same reason why scraping is better than surface grinding and the reasons why scraping is slowing disappearing.Shapers in the past were certainly a goto option for flattening surfaces. Most steam engine plans from the early to mid 1900s included machining surfaces on the shaper rather then the lathe which is the modern goto option.

The issue is fewer and fewer large shapers out there to surface long faces.

There was a thread on machining a 36" straight edge that used a 6' long rockford planer.. and a video on youtube I found a few years ago and saved... even though I will never have a large shaper

Tom Kitta

Ultra Member

Planers are nice but they are big machines of mostly historical significance. They are not exactly (AFAIK) hobby sized machines - some smaller models did get into some very large hobby shops.

Grinding and scraping are not mutually exclusive, both have pluses and minuses thus saying one is better then other is a bit misleading without saying "for what". Certainly scraping is much cheaper to achieve very flat surface then grinding at home shop level where labor is more or less free given high experience of such scraper. However, for modern machinery its mostly grinding that is done, it is quite cheap, can be done with hardened stuff and results can be very good. For ultra precision grinding also beats scraping - but its not like everyone has access to million dollar plus equipment. I certainly would not mind learning to scrape (or at least flake) useful skill to have but I am not planning on selling my SG as well.

Grinding and scraping are not mutually exclusive, both have pluses and minuses thus saying one is better then other is a bit misleading without saying "for what". Certainly scraping is much cheaper to achieve very flat surface then grinding at home shop level where labor is more or less free given high experience of such scraper. However, for modern machinery its mostly grinding that is done, it is quite cheap, can be done with hardened stuff and results can be very good. For ultra precision grinding also beats scraping - but its not like everyone has access to million dollar plus equipment. I certainly would not mind learning to scrape (or at least flake) useful skill to have but I am not planning on selling my SG as well.

There was a thread on machining a 36" straight edge that used a 6' long rockford planer.. and a video on youtube I found a few years ago and saved... even though I will never have a large shaper

up until a few years ago, Standard Modern roughed the beds out on a 20' planer. BIG machine. After planing, they were ground on a gang wheel grinder, only one I've seen like it. A single shaft with multiple wheels. The wheels were spaced and dressed such that they ground all the way surfaces in one setting. IT was large as well, could do a 20 foot bed.

Some old lathes, and some high quality ones, were just carefully planed as the final finish. Below is a shot of my Holbrook B8 bed way before scraping; the planer marks are clearly visible. I never thought it made a lot of sense from a tribology point of view, but as a maker, they don't get much better than Holbrook so figured I was wrong or was missing something. The bed now is fully scraped, its less than two tenths deviation between any pairs way of way geometry over their length.

Last edited:

Keller Machine was the guy in Kingston.

No idea if they are still doing it or around. I've not used them, but had a lot of discussions and I liked the guy. Seemed very capable and had a good attitude - I'm fussy, and he was as or more so. Bed comes in the day before to acclimatize, super light cuts to avoid heat build up, etc. I did refer someone to him who needed some brake press dies ground and he thought positively of the experience. At one point, Keller wanted me to teach his guys scraping. I figured he was maybe 1/2 (or more) joking, but as I'd rather stick pins in my eye's, I didn't press the point lol.

No idea if they are still doing it or around. I've not used them, but had a lot of discussions and I liked the guy. Seemed very capable and had a good attitude - I'm fussy, and he was as or more so. Bed comes in the day before to acclimatize, super light cuts to avoid heat build up, etc. I did refer someone to him who needed some brake press dies ground and he thought positively of the experience. At one point, Keller wanted me to teach his guys scraping. I figured he was maybe 1/2 (or more) joking, but as I'd rather stick pins in my eye's, I didn't press the point lol.

Last edited:

trlvn

Ultra Member

Pretty sure Preston Rebuilt Machinery and Red / Cam Machinery are one and the same. At least, they have exactly the same contact email ([email protected]).Yeah... Red/Cam Man. would be in the same complex so that would have made things easier (I don't leave my place often), but it's so close that I can integrate a visit w/ my next set of errands @TorontoBuilder.

Craig

trlvn

Ultra Member

Interesting! They have a web site and the Capabilities page mentions machine repairs and rebuilds:The possibility did not come from a directory where a member stated they knew a company provided a service, but worth a shot.

Woodstock precision machinery. The list restoration services on their website.

VISIT US

200 Universal Rd, Unit 4 Woodstock, Ontario N4S7W3

OPEN OFFICE HOURS

M-T: 8am- 5pm FRI: 8am – 3pm

S-S: Closed

CONTACT US

519-539-3321

[email protected]

Capabilities

Craig

boilerhouse

Ultra Member

Please update this thread as you learn more. Many of us would like to discover more about this type of service and first hand information would be fantastic.Thanks for all the info. I have contacted these places to see if anyone was interested.

Howder1951

Member

When I was still working the "mill" purchased a re-conditioned lathe which was very nice. I think the ways were ground true and the parts running on them were re-surfaced with a glue-on material that can be scraped to fit called turcite