After years of dithering I decided to bite the bullet. Its a 12x18x3" Grade B (overall unilateral flatness tolerance: ±0.0001"). Sourced from Sowa in Edmonton procured through DMH in Calgary.

So the journey begins. I have to make a proper protection lid, for now 1/8" hardboard.

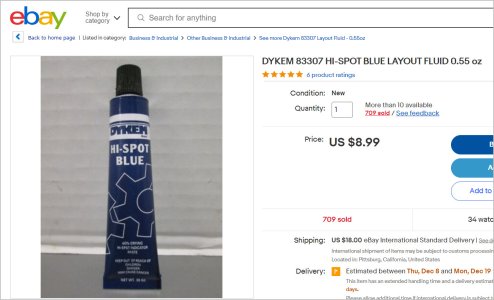

Does anyone have some favorite suppliers of bluing goop? I have a small tube somewhere, I'm actually not even sure its the same stuff. I see people have these hard rubber rollers to evenly distribute on the granite, is that like an art supply item maybe?

www.sowatool.com

www.sowatool.com

So the journey begins. I have to make a proper protection lid, for now 1/8" hardboard.

Does anyone have some favorite suppliers of bluing goop? I have a small tube somewhere, I'm actually not even sure its the same stuff. I see people have these hard rubber rollers to evenly distribute on the granite, is that like an art supply item maybe?

12"x18" Grade B Black Granite Surface Plate - Inspection Surface Plates

12"x18" Grade B Black Granite Surface Plate - • Brand: STM<br>• Color : Black<br>• Material : Granite<br>• Overall Unilateral Flatness Tol. (Decimal Inch) : ±0.0001<br>• <a href="/INTERSHOP/static/BOS/Sowa-Site/Webshop_CA/Sowa-Webshop_CA/en_US/Catalogue-Pages/F20.pdf">Download catalogue page</a>