-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gcode for Duplex Receptacle

- Thread starter slow-poke

- Start date

slow-poke

Ultra Member

I expect you will have to model that up yourself.

I found it in Mach3 wizard, but unfortunately it does not seem to actually generate the code

Are you wanting just the holes to be able to mount an outlet inside a box or a custom panel?Does anyone have a gcode program for the old style duplex receptacle?

x=y=0 @ center mounting screw

1/8" tool diameter

Attachments

Doggggboy

Ultra Member

CHAT GPT will generate Gcode apparentlyDoes anyone have a gcode program for the old style duplex receptacle?

x=y=0 @ center mounting screw

1/8" tool diameter

slow-poke

Ultra Member

Front panel, I just strung a bit off G code together, it's running now. ThanksAre you wanting just the holes to be able to mount an outlet inside a box or a custom panel?

slow-poke

Ultra Member

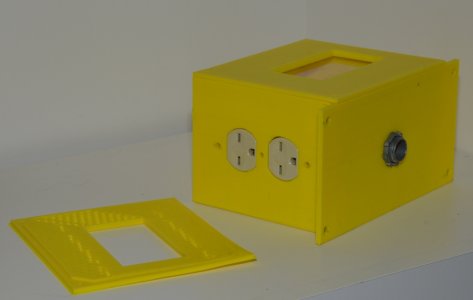

Something like this.....

It's a bit of an unusual configuration, 3 x duplex

Required 8 lines of gCode plus the unused baggage:

(Duplex Top)

G0 G49 G40 G17 G80 G50 G90

M6 T5(TOOL DIA. 0.125)

G20 (Inch)

M03 S300

G64

G00 G43 H5 Z0

(right arc)

X0.3246 Y0.2546

G01 Z-0.1 F0.5

G3 X0.3246 Y1.2934 I0 J0.774 F0.15

(straight left)

G1 X -0.3246 F0.15

(Left arc)

X-0.3246 Y1.2934

G01 Z-0.1 F0.5

G3 X-0.3246 Y0.2546 I0 J0.774 F0.15

(straight right)

G1 X 0.3246 F0.15

G00 Z0

M5 M9

M30

It's a bit of an unusual configuration, 3 x duplex

Required 8 lines of gCode plus the unused baggage:

(Duplex Top)

G0 G49 G40 G17 G80 G50 G90

M6 T5(TOOL DIA. 0.125)

G20 (Inch)

M03 S300

G64

G00 G43 H5 Z0

(right arc)

X0.3246 Y0.2546

G01 Z-0.1 F0.5

G3 X0.3246 Y1.2934 I0 J0.774 F0.15

(straight left)

G1 X -0.3246 F0.15

(Left arc)

X-0.3246 Y1.2934

G01 Z-0.1 F0.5

G3 X-0.3246 Y0.2546 I0 J0.774 F0.15

(straight right)

G1 X 0.3246 F0.15

G00 Z0

M5 M9

M30

Mine was bigger because I did a depth of cut 0.050. Plus entry exit ramps. That was for the inner profile. One of the programs milled it all away. Tedious.

Former Member

Guest

Look at the feed rate 0.15.... I'd be running 5 at least.

slow-poke

Ultra Member

I wanted tight corners so I used a small diameter tool, I start slow on the first pass, then speed up when I know it's working. Can you cut at 5 IPS with a 1/8" tool?Look at the feed rate 0.15.... I'd be running 5 at least.

Oh and mine was also a good example of crap CAM software from Mecsoft which used a whole bunch of short lines rather than the IJ curves. Which just goes to show that if you learn how G-Code works it's possible to make small programs.Mine was bigger because I did a depth of cut 0.050. Plus entry exit ramps. That was for the inner profile. One of the programs milled it all away. Tedious.

slow-poke

Ultra Member

I imagine anyone that has written even a few lines of machine code cringes when they download some trivial program like a clock, and it requires 500MB or more of disc space. I know I do.;-)Oh and mine was also a good example of crap CAM software from Mecsoft which used a whole bunch of short lines rather than the IJ curves. Which just goes to show that if you learn how G-Code works it's possible to make small programs.