Ya the Clickspring freehand method is essentially how I did my venturi's by eye, although I have yet to make a proper steady bar or whatever you call it. But if the curvy shape has to conform to something semi-accurately, then 100% freehand gets a bit iffy. You would have to hold up a template or something I guess to compare progress or something like that.

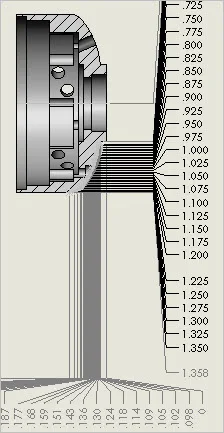

The Eccentric method is also an ornamental/freehand, but it has the capability of being something more precise & repeatable with just a 2D template, kind of like a 1:1 pantograph follower principle. But I have to figure how to make a good base plate datum, that's an integral feature.