David Brooks

New Member

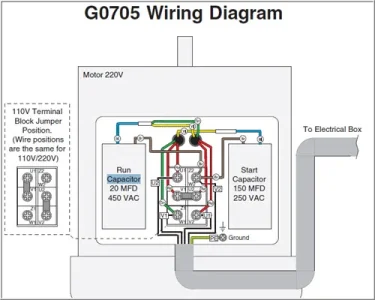

I recently purchased a mill drill machine in need of repair. previous owner had a problem with the start capacitor and removed it and tossed it in the garbage. now i need to know what size of capacitor to put into it to get it to work. I thought if someone had the same mill they could get the numbers off their machines capacitor. Any help would be appreciated .

![IMG_0254[1].JPG](/data/attachments/0/843-e4d9a50fc4b941a6a035048e76e7d134.jpg?hash=G4qXkRBDU4)