I need to sell my Machine Tools Warehouse MD001 mill that has been converted to CNC by me...

Located in east end of Ottawa (Orleans).

First - the MTW MD001 is a clone of the ZAY 12Z mill which is a beefed up version of the RF45 mill... I think its somewhere between 750 and 900lbs.

Travel as programmed

X - 24" (609mm)

Y - 11" (279mm)

Z - 18" (457mm)

VFD controlled spindle motor - VFD rated 3hp, motor 1500W (2hp), 1700 RPM but can safely be run at double the rpm.

Max velocities - set to 60ipm but capable of 100ipm+

300W servos and drives on x and y, 600w on Z

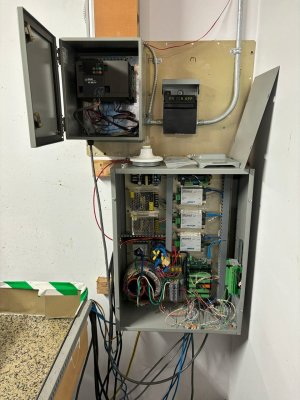

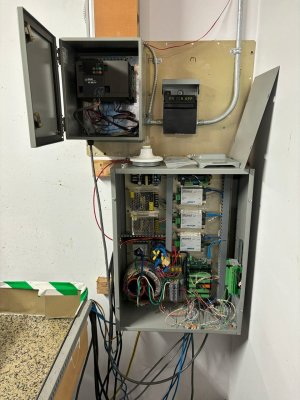

Control is through LinuxCNC using a MESA 7i76E (ethernet) card.

uses 240VAC for control system input voltage and for spindle (I use 2 separate supplies).

oil system for ways

Tool setter probe

air / coolant spray setup

It will go with the 4th stepper motor driver and power supply built into the control cabinet so you would just need to add your own rotary table and stepper motor.

Left overs from the manual conversion - only Y-axis lead screw still around and a few other small items.

Brand new replacement 30 taper spindle (bought just in case of a major crash as they seem hard to find)

Tooling: quite a bit - this is where the value is. All but one (shown with the spare spindle) are NMTB-30 (i.e. use 1/2"-13 draw bar). includes 2 drill chucks, ER40 collets, a couple of fly cutters and a tapping head plus end mill holders and extra J taper drill chuck adapters. If you are just getting into machining I can probably toss in a handful of end mills too to get you started.

Not included are the vice and the 4th axis (Rotary table and stepper motor) I'm keeping it for the new mill, and the electrical disconnect switch on the wall.

The ballscrews have backlash. ideally this would be addressed with the addition of a second ballnut that is preloaded. Currently just using backlash comp in the control. Mostly just an issue on small end mills (sub 1/8") which the spindle doesn't have the speed to use properly anyways.

The "enclosure" is incomplete and leaks... the doors do work to keep you free of most debris, I just never fully rebuilt the enclosure after I moved houses. The pan leaks so I don't use flood coolant, just air / mist cooling.

1 big hole in the table otherwise almost no marks (use the vice mostly).

Electrical cabinets do have doors, just off for pictures.

Lightly used since built - best guess is I averaged anywhere from 0 to 5 hours a month on it since I built it (2010).

NOT separating tooling and the mill - they go together.

Asking $3500 obo (motivated - come see and make an offer)

Currently powered and can show but that will change soon as I need to move it from the basement - it will ship out in pieces to my garage, where it will likely not be reassembled.

Located in east end of Ottawa (Orleans).

First - the MTW MD001 is a clone of the ZAY 12Z mill which is a beefed up version of the RF45 mill... I think its somewhere between 750 and 900lbs.

Travel as programmed

X - 24" (609mm)

Y - 11" (279mm)

Z - 18" (457mm)

VFD controlled spindle motor - VFD rated 3hp, motor 1500W (2hp), 1700 RPM but can safely be run at double the rpm.

Max velocities - set to 60ipm but capable of 100ipm+

300W servos and drives on x and y, 600w on Z

Control is through LinuxCNC using a MESA 7i76E (ethernet) card.

uses 240VAC for control system input voltage and for spindle (I use 2 separate supplies).

oil system for ways

Tool setter probe

air / coolant spray setup

It will go with the 4th stepper motor driver and power supply built into the control cabinet so you would just need to add your own rotary table and stepper motor.

Left overs from the manual conversion - only Y-axis lead screw still around and a few other small items.

Brand new replacement 30 taper spindle (bought just in case of a major crash as they seem hard to find)

Tooling: quite a bit - this is where the value is. All but one (shown with the spare spindle) are NMTB-30 (i.e. use 1/2"-13 draw bar). includes 2 drill chucks, ER40 collets, a couple of fly cutters and a tapping head plus end mill holders and extra J taper drill chuck adapters. If you are just getting into machining I can probably toss in a handful of end mills too to get you started.

Not included are the vice and the 4th axis (Rotary table and stepper motor) I'm keeping it for the new mill, and the electrical disconnect switch on the wall.

The ballscrews have backlash. ideally this would be addressed with the addition of a second ballnut that is preloaded. Currently just using backlash comp in the control. Mostly just an issue on small end mills (sub 1/8") which the spindle doesn't have the speed to use properly anyways.

The "enclosure" is incomplete and leaks... the doors do work to keep you free of most debris, I just never fully rebuilt the enclosure after I moved houses. The pan leaks so I don't use flood coolant, just air / mist cooling.

1 big hole in the table otherwise almost no marks (use the vice mostly).

Electrical cabinets do have doors, just off for pictures.

Lightly used since built - best guess is I averaged anywhere from 0 to 5 hours a month on it since I built it (2010).

NOT separating tooling and the mill - they go together.

Asking $3500 obo (motivated - come see and make an offer)

Currently powered and can show but that will change soon as I need to move it from the basement - it will ship out in pieces to my garage, where it will likely not be reassembled.

Last edited: