Doggggboy

Ultra Member

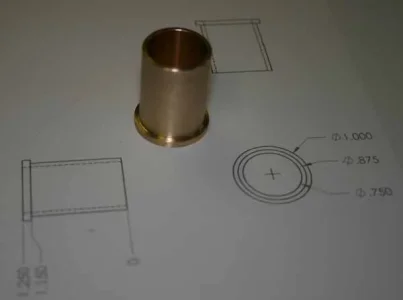

I am trying to repair a car lift and need to replace a worn bushing on one of the cable pulleys.

The axle is 20 mm and the pulley bore is 22.5 mm.

Of course I can't find anything that size so my plan is to use a 5/8 x1 inch bushing.

I should be able to bore out the pulley to accept the bushing on the mill, press it in and then bore out the bushing to accept the axle.

This is not a high speed assembly, just routes the cable from the ram to the post at each corner of the lift.

What size should I shoot for to accept the bushing for a nice press fit?

I haven't actually measured the od of the bushing yet, just looking for some guidance on tolerances.

This will be my first attempt at making a useful part with the boring head so I got a pack of 4 bushings at PA.

The axle is 20 mm and the pulley bore is 22.5 mm.

Of course I can't find anything that size so my plan is to use a 5/8 x1 inch bushing.

I should be able to bore out the pulley to accept the bushing on the mill, press it in and then bore out the bushing to accept the axle.

This is not a high speed assembly, just routes the cable from the ram to the post at each corner of the lift.

What size should I shoot for to accept the bushing for a nice press fit?

I haven't actually measured the od of the bushing yet, just looking for some guidance on tolerances.

This will be my first attempt at making a useful part with the boring head so I got a pack of 4 bushings at PA.