Hey All, Haven't been posting much lately, but have been busy working on this project, so want to share an update!

I finally got rid of that beast of a horizontal air compressor (~500lbs, cast iron, awful) I've had in my shop for two years now in favour of a vertical compressor.

Moving compressor home: (scary unloading this solo)

That last pump of the engine hoist when you know it's coming off the truck is terrifying, haha.

Next up was setting up a home-made auto tank drain. Really it's just a 12V actuated air solenoid valve:

Hooked to a timer. The line was been snaked through the shop out the garage door. The little bit of plastic tube sticking out of the garage may freeze solid in the winter, now sure yet, but will update when I know.

I have a little sandblaster, and want to get into paint, but historically moisture was always an issue, as I didn't have enough distance from the compressor for the water to condense out. As I want to plumb my garage anyways, I spent the tail end of my weekend getting started with plumbing copper lines into the shop.

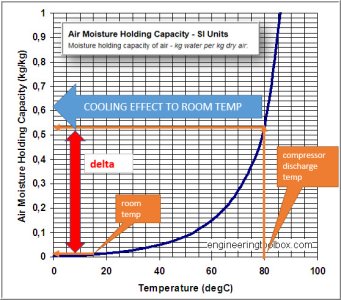

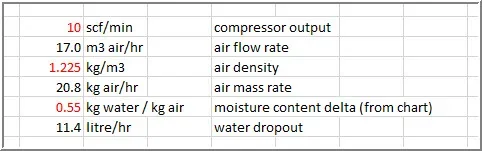

First step though, was getting the water to drop out by cooling the air to room temp.

I plan to pull the wood down and paint to match the decor, but for now just wanted to get working on the piping.

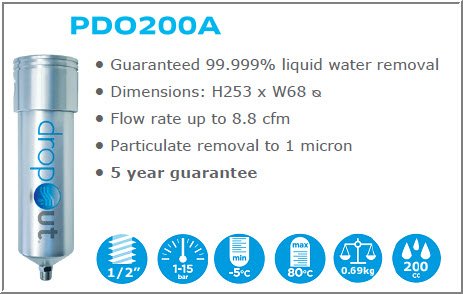

I found several sources and did alot of math before finally settling on 1/2" copper, and the above design for cooling the air, while maintaining a heavy slope to gather the water at the bottom. (Not done yet).

The above is where I left off before bed, hopefully make some more progress tonight.

I plan to make one more u-turn with the pipe at the bottom, to a T fitting with a drip leg. From there distribute to 6-8 locations across the garage (one per side, one per corner).

I've also decided sweating/soldering copper is pretty fun. Will likely work with it in future too!

Will take some more pics as I go.

JW

I finally got rid of that beast of a horizontal air compressor (~500lbs, cast iron, awful) I've had in my shop for two years now in favour of a vertical compressor.

Moving compressor home: (scary unloading this solo)

That last pump of the engine hoist when you know it's coming off the truck is terrifying, haha.

Next up was setting up a home-made auto tank drain. Really it's just a 12V actuated air solenoid valve:

Hooked to a timer. The line was been snaked through the shop out the garage door. The little bit of plastic tube sticking out of the garage may freeze solid in the winter, now sure yet, but will update when I know.

I have a little sandblaster, and want to get into paint, but historically moisture was always an issue, as I didn't have enough distance from the compressor for the water to condense out. As I want to plumb my garage anyways, I spent the tail end of my weekend getting started with plumbing copper lines into the shop.

First step though, was getting the water to drop out by cooling the air to room temp.

I plan to pull the wood down and paint to match the decor, but for now just wanted to get working on the piping.

I found several sources and did alot of math before finally settling on 1/2" copper, and the above design for cooling the air, while maintaining a heavy slope to gather the water at the bottom. (Not done yet).

The above is where I left off before bed, hopefully make some more progress tonight.

I plan to make one more u-turn with the pipe at the bottom, to a T fitting with a drip leg. From there distribute to 6-8 locations across the garage (one per side, one per corner).

I've also decided sweating/soldering copper is pretty fun. Will likely work with it in future too!

Will take some more pics as I go.

JW

Last edited: