Wally

Member

While pretty simple compared to a lot of the projects I see on here I thought I'd post my very first welding project since taking up the hobby. Learned a bunch and reinforced a lot of the things I should have learned in the You-Tube videos I've been watching.

The three that pop out the most is first, tack EVERYTHING together first, check for square and level then start welding , trying to not putting to much heat into any one area at a time.

Second, practice the route your going to weld first to make sure you dont get jammed halfway though a weld. Forgetting this one makes for some ugly welds and a lot of grinding, which takes us to the third learning moment.

Don't forget to change that new Auto-Darkening helmet back to "Weld" after using it to grind. Real hard to weld when your vision has a big green dot in the middle because you forgot that last one.

Next project, a proper welding table.

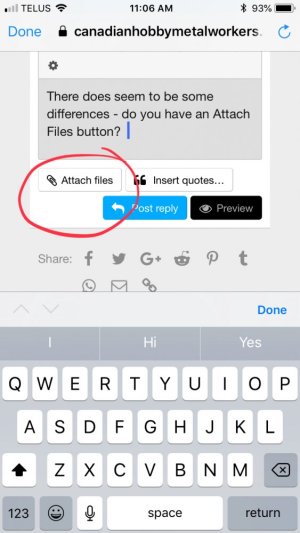

I'll post a couple pics once I figure out how, not letting me at the moment. I looked at the posting pictures thread and still not clear on what I need to do or if I can from my iPad Any advice anyone has would be appreciated.

The three that pop out the most is first, tack EVERYTHING together first, check for square and level then start welding , trying to not putting to much heat into any one area at a time.

Second, practice the route your going to weld first to make sure you dont get jammed halfway though a weld. Forgetting this one makes for some ugly welds and a lot of grinding, which takes us to the third learning moment.

Don't forget to change that new Auto-Darkening helmet back to "Weld" after using it to grind. Real hard to weld when your vision has a big green dot in the middle because you forgot that last one.

Next project, a proper welding table.

I'll post a couple pics once I figure out how, not letting me at the moment. I looked at the posting pictures thread and still not clear on what I need to do or if I can from my iPad Any advice anyone has would be appreciated.

Last edited: