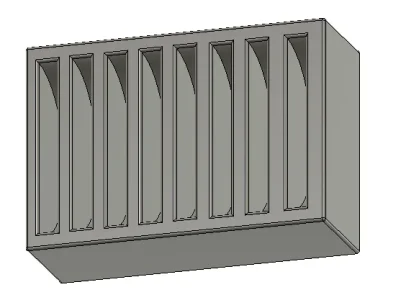

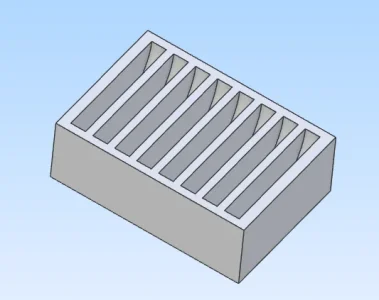

I received my gear cutters last week and I thought that with my new 3D printer I'd like to design a holder for them.

Drew this up in Fusion simply because I found a tutorial on how to design tool holders.

It was a bit tricky because the 'Arrange' feature is disabled for hobbyist so I had to manually arrange the slots instead of letting the program auto arrange them across the face of the part.

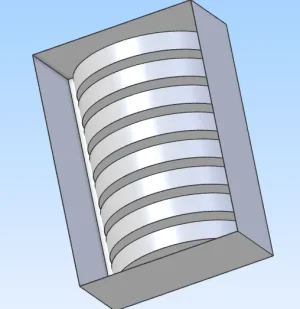

I have since tried to replicate in Atom 3D and I'm a bit stumped.

Drew this up in Fusion simply because I found a tutorial on how to design tool holders.

It was a bit tricky because the 'Arrange' feature is disabled for hobbyist so I had to manually arrange the slots instead of letting the program auto arrange them across the face of the part.

I have since tried to replicate in Atom 3D and I'm a bit stumped.