DPittman

Ultra Member

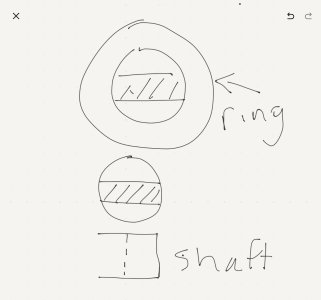

Forgive my lack of CAD or any resemblance or talent regarding a drawing but that's all I can do.

I'm trying to mill a blind slot in an aluminum pulley for the end of a motor shaft to fit in.

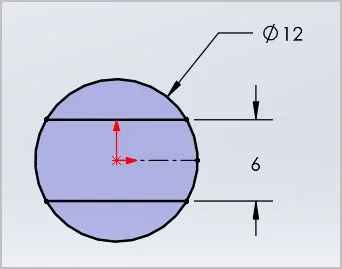

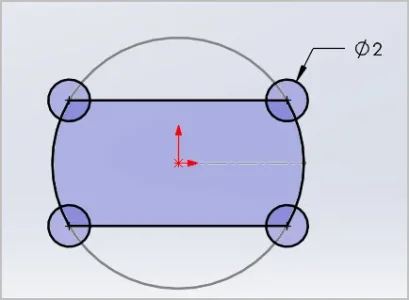

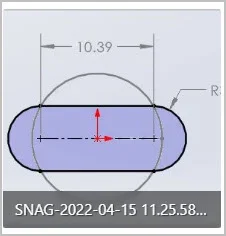

The shaft started out as a 12mm diameter but was milled on two sides to make a 6mm wide "bar" but with 12mm radius ends. (This was factory done on an electric die grinder).

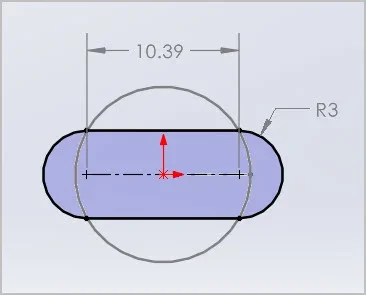

I milled the slot in the aluminum using a 6mm end mill but of course ended up with 6mm radius ends instead of 12mm.

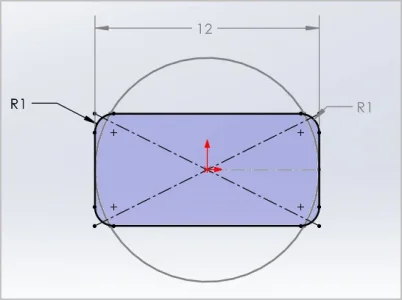

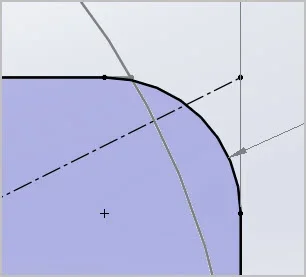

Is there some redneck math/way I could figure out how to mill the end corners a bit more to get the shaft to fit? I don't really want to overshoot the slot length a whole bunch past the right length but I guess that might be one way.

I'm guessing if there is a way it's probably above my pay grade but I thought I would ask just in case.

I'm trying to mill a blind slot in an aluminum pulley for the end of a motor shaft to fit in.

The shaft started out as a 12mm diameter but was milled on two sides to make a 6mm wide "bar" but with 12mm radius ends. (This was factory done on an electric die grinder).

I milled the slot in the aluminum using a 6mm end mill but of course ended up with 6mm radius ends instead of 12mm.

Is there some redneck math/way I could figure out how to mill the end corners a bit more to get the shaft to fit? I don't really want to overshoot the slot length a whole bunch past the right length but I guess that might be one way.

I'm guessing if there is a way it's probably above my pay grade but I thought I would ask just in case.