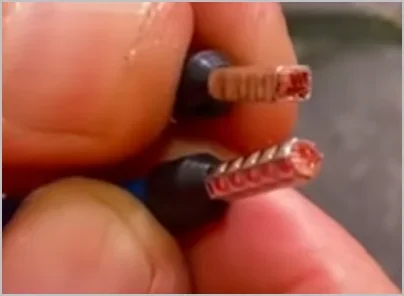

I need to do some hobby project wiring in the 14-12 gauge range of stranded wire. I'm interested in this square section crimp style vs the typical ring & spade stuff which I never really got along with.

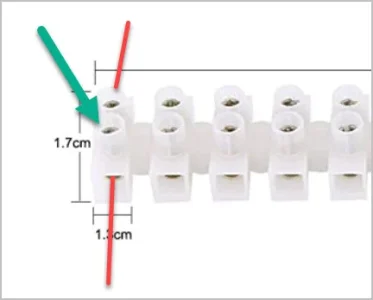

But what I'm fuzzy on is the matching generic (I think they are called) terminal blocks. What do these crimped square ends plug into when you need to make strip connections like the conventional screw down style for ring & spade? Can someone point me to a system that is common / reasonable cost. FWIW I recently placed a DigiKey order & they were super speedy & reasonable delivery if you happen to source from there.

But what I'm fuzzy on is the matching generic (I think they are called) terminal blocks. What do these crimped square ends plug into when you need to make strip connections like the conventional screw down style for ring & spade? Can someone point me to a system that is common / reasonable cost. FWIW I recently placed a DigiKey order & they were super speedy & reasonable delivery if you happen to source from there.