slow-poke

Ultra Member

My mill runs under Mach3 with Win7 (16) as if on an island with no network (by design). I figure I have saved a life time of headaches not having to live with all the things that break with Win updates virus checking etc. So far it has been completely trouble free for many years so I would like to keep it that way.

Looking for a feeds and speeds calculator that will run under Win7, that I can download on my regular PC and then install on the mill PC with just the install program on a USB stick.

If I have to pay for one I will but would prefer a free version if a decent one exists.

HSM advisor appears to require payment after 30 days

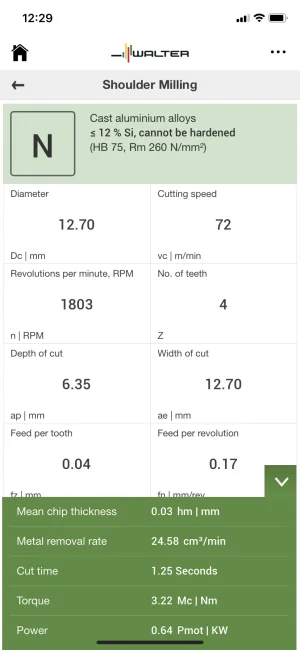

FSWizard seems to be more of an App for a phone, and the online version will not work on my island.

Any suggestions?

Looking for a feeds and speeds calculator that will run under Win7, that I can download on my regular PC and then install on the mill PC with just the install program on a USB stick.

If I have to pay for one I will but would prefer a free version if a decent one exists.

HSM advisor appears to require payment after 30 days

FSWizard seems to be more of an App for a phone, and the online version will not work on my island.

Any suggestions?