-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Faceplate on a chuck?

- Thread starter DavidR8

- Start date

Tool

140mower

Don

I'm not sure that I would be comfortable hanging the faceplate plus whatever awkward thing that wouldn't fit in the chuck that far out.

What spindle mount does it have? I would be more inclined to try and replicate that and make it a two piece affair if required.

Those are my thoughts, probably only worth 1/3 the going rate however......

What spindle mount does it have? I would be more inclined to try and replicate that and make it a two piece affair if required.

Those are my thoughts, probably only worth 1/3 the going rate however......

This is a good point.I'm not sure that I would be comfortable hanging the faceplate plus whatever awkward thing that wouldn't fit in the chuck that far out.

What spindle mount does it have? I would be more inclined to try and replicate that and make it a two piece affair if required.

Those are my thoughts, probably only worth 1/3 the going rate however......

My lathe has a 1.5 x 8 TPI spindle.

Maybe this is the ‘opportunity’ to learn how to do an inside thread?

Are you thinking about machining a hub to match spindle then permanently attaching plate disc, then turning assembly true in-situ? Or is that just how I might do it? LOL

Depending on your spindle & other factors, doing it all in one shot might require a different approach. You probably have seen faceplates but give some consideration to how you want to mount things, either the classic slots or maybe a gridded tooling plate concept.

Depending on your spindle & other factors, doing it all in one shot might require a different approach. You probably have seen faceplates but give some consideration to how you want to mount things, either the classic slots or maybe a gridded tooling plate concept.

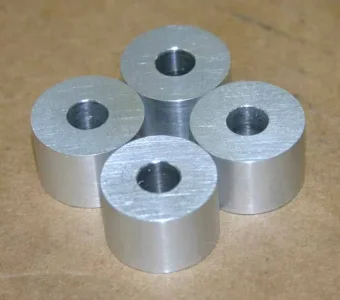

Attachments

I'm not sure that I would be comfortable hanging the faceplate plus whatever awkward thing that wouldn't fit in the chuck that far out.

Are you maybe thinking bigger chuck in a smaller one? I wouldn't do that either.

I was thinking smaller chuck mounted in a bigger one to hold smaller stuff that can't be held in a big chuck very well.

Tomc938

Ultra Member

I like the looks of that!Are you thinking about machining a hub to match spindle then permanently attaching plate disc, then turning assembly true in-situ? Or is that just how I might do it? LOL

Depending on your spindle & other factors, doing it all in one shot might require a different approach. You probably have seen faceplates but give some consideration to how you want to mount things, either the classic slots or maybe a gridded tooling plate concept.

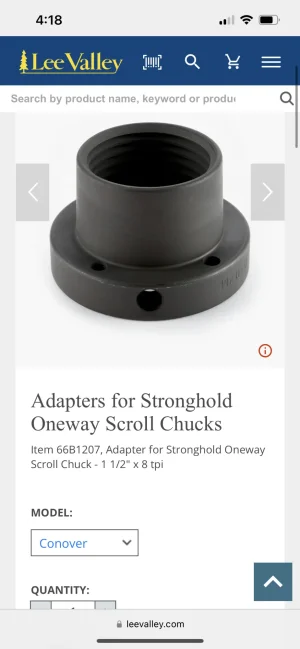

You answered while I was still typing. You might be able to source a chuck adapter already nicely threaded to act as a hub, then that just leaves you to permanently mount your disc & turn it in-situ. That's kind of what was driving at.My lathe has a 1.5 x 8 TPI spindle.

Maybe this is the ‘opportunity’ to learn how to do an inside thread?

No it went with the South BendYou didn't keep the one @Brent H made for you?

Also just to confirm, when some guys say face plate, they might be intending its use as what is better referred to as a drive plate, which has dedicated slot or pin provision for acting on the dog leg for turning between centers. Some people insert the dog into face plate slots, but its arguably more appropriate to use face plate slots more how like conventional T-slots are used, to hold parts & fixtures. You don't see drive plates much these days but I suspect I will be making one for next project, harvesting a D1-4 chuck adapter similar to what I described.

I’ve seen chuck adaptors for wood lathes so I’ll do some investigating that direction.You answered while I was still typing. You might be able to source a chuck adapter already nicely threaded to act as a hub, then that just leaves you to permanently mount your disc & turn it in-situ. That's kind of what was driving at.

No matter what it’s will be a two-piece affair; hub and then a plate welded to the hub and machines in situ.

My lathe came with a drive plate fortunately.Also just to confirm, when some guys say face plate, they might be intending its use as what is better referred to as a drive plate, which has dedicated slot or pin provision for acting on the dog leg for turning between centers. Some people insert the dog into face plate slots, but its arguably more appropriate to use face plate slots more how like conventional T-slots are used, to hold parts & fixtures. You don't see drive plates much these days but I suspect I will be making one for next project, harvesting a D1-4 chuck adapter similar to what I described.

No matter what it’s will be a two-piece affair; hub and then a plate welded to the hub and machines in situ.

Why two piece? I got a 1.5X8 drive plate on Ebay, I'm sure there are face plates out there as well.

@140mower Anything in your Southbend stash?

I haven’t looked to be honest.Why two piece? I got a 1.5X8 drive plate on Ebay, I'm sure there are face plates out there as well.

@140mower Anything in your Southbend stash?

Just seems like something a fellow would make.

Maybe this is the ‘opportunity’ to learn how to do an inside thread?

Prolly my very next lathe job will be to make some hitch pin extensions that will be inside threaded to match some Category II - 3pt hitch pin studs so I can rest my Ripper on a rolling stand in the barn. It's a 7/8ths thread but would be similar to what you want to do. The primary difference is that yours will be a through hole and mine will be a blind hole. If you decide to do it, I could slow down my project enough to do it with you and take photos to answer any questions you might have....

140mower

Don

Yup, and while you are at it make yourself an er collet chuck to match whatever one you pick for the new mill.....This is a good point.

My lathe has a 1.5 x 8 TPI spindle.

Maybe this is the ‘opportunity’ to learn how to do an inside thread?

140mower

Don

Yup, I was thinking about the idea of removing the top jaws and bolting on a full size face plate to the lower jaws...... That gets to be quite a bit of weight on its own before adding the work piece and the additional overhang... (My mind's eye has a cast iron 8 hp Kohler engine block spinning around a long boring bar)Are you maybe thinking bigger chuck in a smaller one? I wouldn't do that either.

I was thinking smaller chuck mounted in a bigger one to hold smaller stuff that can't be held in a big chuck very well.

Any face plates or chuck back plates?I think I might have a half dozen or so extra drive plates.......ok, I know that I do....lol