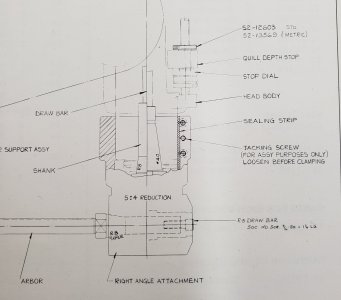

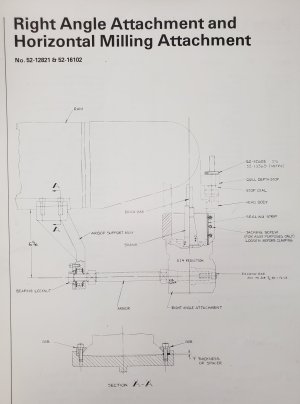

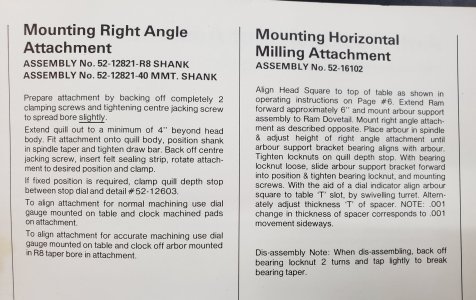

I just picked up an Ex-Cell-O right angle attachment from an auction. They came to fit either an R8 spindle machine or a #40. My Ex-Cell-O 602 is a #40. I was hoping, in fact praying, that the attachment was for my machine. Well, not so lucky. So I'll have to figure something out. Either make a #40 shank, or use my #40-R8 adapter sleeve, which is being used on a boring head (in a previous post I started a while ago.) I'll take it apart and have a look inside. Maybe @LenVW

has some insight since he worked at Ex-Cell-O many years ago.

has some insight since he worked at Ex-Cell-O many years ago.

Attachments

Last edited: