calgaryguy

Chris

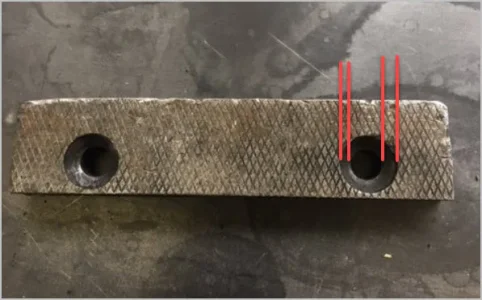

I've got a Eron No.125 bench vise I inherited from my grandfather. Its been *heavily* used and abused by my dad and I over the years. Today I disassembled it, cleaned 60+ years of shit out of it, and reassembled. Works like new. It does however need a new set of jaws.

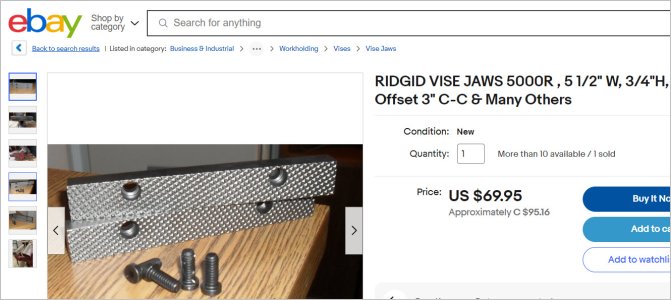

the Eron No. 125 is a 5" bench vise and has what I would call 'offset' screw holes in the jaws. I'll update this post with a pic as soon as I take one.

Any ideas where to source replacement jaws?

the Eron No. 125 is a 5" bench vise and has what I would call 'offset' screw holes in the jaws. I'll update this post with a pic as soon as I take one.

Any ideas where to source replacement jaws?