-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engraving endmill

- Thread starter Tom O

- Start date

DPittman

Ultra Member

10000 rpm holy cow. Can they be used successfully on bridgeport/clone machine? Those machines don't dothat high rpm do they?I use this kind.

I could spare a couple.

What are you using for a spindle? They need a high rpm 10,000 or more.

Tom O

Ultra Member

The Haas tops out at 6000 rpmI use this kind.

I could spare a couple.

What are you using for a spindle? They need a high rpm 10,000 or more.

DPittman

Ultra Member

Oh my gosh, I guess I should have read closer, that's a TINY tip.They’re meant to run in CNC routers. The tip is only 0.2mm diameter.

I use the micro 100 engraving tools at work.

www.micro100.com

www.micro100.com

Engraving Cutters-Tipped Off-Single Ended

Tom O

Ultra Member

Do you know if there‘s anywhere in Calgary that have them in stock? I like the flat tip.I use the micro 100 engraving tools at work.

Engraving Cutters-Tipped Off-Single Ended

www.micro100.com

I've been doing a bit of engraving (picture attached) in stainless and brass.

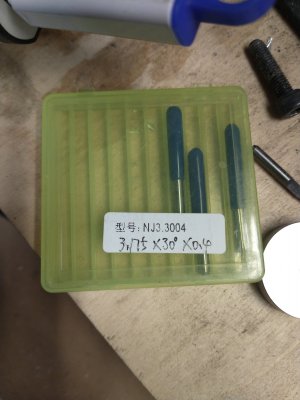

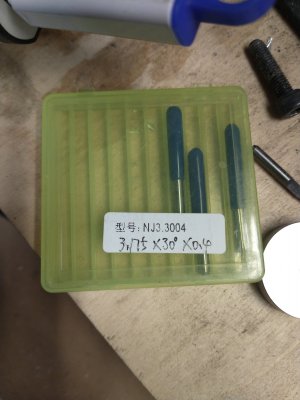

Attached is a picture of the bits I used,

These are 30degree with a 0.4mm flat on the bottom and do ok. This is on a router running at like 16k rpm and a D.O.C of I think 0.1mm, then a 2nd pass at 0.175mm.

I ordered them from China, depending on what you're doing I could probably help you out. You won't be able to reasonably run these on something like a Bridgeport, you'll need to be at least in the 10k or greater range.

Attached is a picture of the bits I used,

These are 30degree with a 0.4mm flat on the bottom and do ok. This is on a router running at like 16k rpm and a D.O.C of I think 0.1mm, then a 2nd pass at 0.175mm.

I ordered them from China, depending on what you're doing I could probably help you out. You won't be able to reasonably run these on something like a Bridgeport, you'll need to be at least in the 10k or greater range.

Johnwa

Ultra Member

I use the micro 100 engraving tools at work.

Engraving Cutters-Tipped Off-Single Ended

www.micro100.com

@Alexander what feeds and speeds do you use?

DGI can order them for you. They don't stock them. Speeds and feeds vary. I use them on heavy machines with 6k rpm spindles and smaller machines with 16k rpm spindles. The tool lasts a long time at around 10k rpm and 10 IPM. It will last about half as long at 6k rpm doing the same feed rate. Keep the plunge really low around 2 inches a minute

I checked the website for https://www.micro100.com and they list Thomas Skinner as their distributor.

Grab some nailpolish, infill and give it a bit of time to cure.. Ideally hours. I wouldn't suggest using acetone to wipe off the excess as it tends to get into the inlay and mess it up, lacquer thinner or even isopropyl seems to cut it much slower, use a lint free cloth in case it does soften the inlay and it won't leave fuzz in there.I got the endmill today and was wondering what you guys use for making it more visible colour wise I asked at Kens Gems and he said felt pen? Any thoughts?

Tom O

Ultra Member

Well I snapped the tip on a dumb move and have ordered another one. We always went to my brothers on Wednesday to watch Survivor that gave him something to look forward to this time Jan told me my niece has a friend that does engraving and will make it I’ll still make one even if it’s for the garage wall.

Bob and Jan raised over 30 foster kids like their own adopting 2, at Xmas and Holidays they went all in. Bob was also President of Applewood for a number of years receiving 2 medals for Community service from the Governor General.

Bob and Jan raised over 30 foster kids like their own adopting 2, at Xmas and Holidays they went all in. Bob was also President of Applewood for a number of years receiving 2 medals for Community service from the Governor General.