I am starting to build the Eureka form relieving tool from Model Engineer, Volume 168.

This gadget cuts the relief behind the cutting edge of a milling cutter, such as these involute gear cutters.

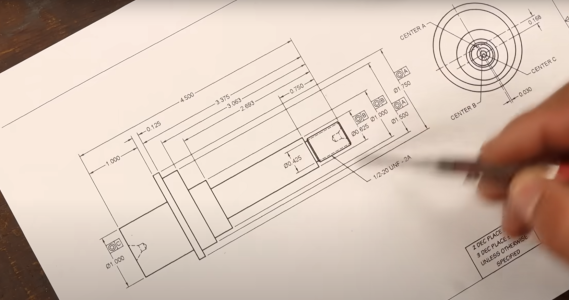

The drawing shows the mandrel which is a triple eccentric turning. I have double-guessed myself a dozen times regarding the order of operations needed. I have a piece of 2-1/2" CRS and some 1-1/4" CRS. If this is turned from solid, that a lot of wasted metal, so I'm leaning towards a two piece assembly with the larger (45,38mm) eccentrics made from 3/8 plate, fitted to the inner 25mm part.

The challenge is indexing the work in the 4-jaw to set the correct 90deg angle when boring the rotational centre pilot which is offset 0.8mm at 90deg to the A centre.

Any tricks and advice appreciated!

This gadget cuts the relief behind the cutting edge of a milling cutter, such as these involute gear cutters.

The drawing shows the mandrel which is a triple eccentric turning. I have double-guessed myself a dozen times regarding the order of operations needed. I have a piece of 2-1/2" CRS and some 1-1/4" CRS. If this is turned from solid, that a lot of wasted metal, so I'm leaning towards a two piece assembly with the larger (45,38mm) eccentrics made from 3/8 plate, fitted to the inner 25mm part.

The challenge is indexing the work in the 4-jaw to set the correct 90deg angle when boring the rotational centre pilot which is offset 0.8mm at 90deg to the A centre.

Any tricks and advice appreciated!