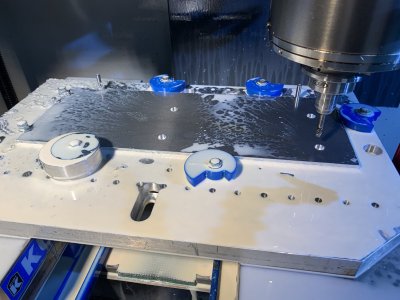

I am making some vise speed handles and I wanted a simpler way to hold down the sheet stock to my fixture plate.

So I made one eccentric aluminium clamp thing and then decided to 3d print the rest. There is a lip to prevent lifting up of the stock on the fixture plate. You turn it until the base contacts the stock - then lock down the bolt. I wonder if it will work?

So I made one eccentric aluminium clamp thing and then decided to 3d print the rest. There is a lip to prevent lifting up of the stock on the fixture plate. You turn it until the base contacts the stock - then lock down the bolt. I wonder if it will work?

Last edited: