-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jimbojones

Active Member

anyone got a force gauge?

- compression spring: center rod and hook/ pulling against block of wood/metal w/hole in center

- extension spring: anchor one end and pull w/gauge on the other

Sans gauge, I've simply resorted to physical size , visual inspection e.g. coil density and thickness and finally...'feel'...then dug around until I found something I liked.

- compression spring: center rod and hook/ pulling against block of wood/metal w/hole in center

- extension spring: anchor one end and pull w/gauge on the other

Sans gauge, I've simply resorted to physical size , visual inspection e.g. coil density and thickness and finally...'feel'...then dug around until I found something I liked.

The way spring design works (roughly) is given: Outside diameter, Wire diameter, Free length, Number of coils, Material... you get a resultant Rate [pounds per inch deflection]. So the more you displace the spring, either tension or compression, the more force it yields. Up to some a maximum force dictated by dimensions (primarily length). What you are asking is the reverse, how much force will your spring inventory give. There is no easy way but just as an example if you needed 5 pounds, you would need to impart that weight on the spring & measure deflection. If that free length & compressed length combination is acceptable to your design, you have your winner. Just realize spring A may yield 5 pounds in 0.1" deflection vs. spring B may yield 5 pounds in 0.6" deflection. They both do the same job, but may have radically different dimensions.

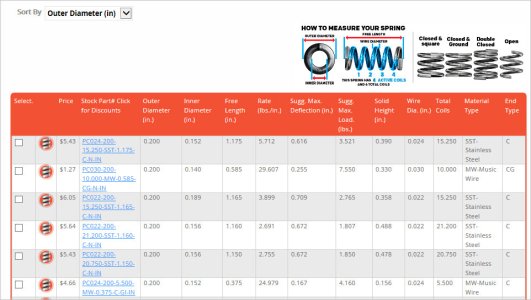

If your springs are out of range then its best to go to some kind of product table or online calculator to get you in the ball park. Attaching table showing variation just around an arbitrary picked OD. When you double & triple OD & wire thickness (like your collection) the forces will vary significantly. https://www.thespringstore.com/spring-calculator.html

But remember this gives you force (like pounds). For a relief valve you need to it to open at some max pressure. So that involves (I assume) also knowing area, like a ball valve seat OD. Pressure = force / area.

I hope you have a relief valve design that specifies everything including spring, ball, seat dimensions & thread. These are all critically important. Don't underestimate a 'toy model' boiler because any compressed gas pack a lot of energy that you don't want to go boom. Especially hot boom. There must be a bunch of designs in the model engineering (live steam) community. This is roughly what they look like (note the pressure setting & number of valves). http://www.americanmodeleng.com/id6.html

If your springs are out of range then its best to go to some kind of product table or online calculator to get you in the ball park. Attaching table showing variation just around an arbitrary picked OD. When you double & triple OD & wire thickness (like your collection) the forces will vary significantly. https://www.thespringstore.com/spring-calculator.html

But remember this gives you force (like pounds). For a relief valve you need to it to open at some max pressure. So that involves (I assume) also knowing area, like a ball valve seat OD. Pressure = force / area.

I hope you have a relief valve design that specifies everything including spring, ball, seat dimensions & thread. These are all critically important. Don't underestimate a 'toy model' boiler because any compressed gas pack a lot of energy that you don't want to go boom. Especially hot boom. There must be a bunch of designs in the model engineering (live steam) community. This is roughly what they look like (note the pressure setting & number of valves). http://www.americanmodeleng.com/id6.html

Attachments

Bofobo

M,Mizera(BOFOBO)

I have no plan, aside from a bunch if parts and a general idea of what i want it to accomplish.

My goals were a relief valve or several of them that could be adjustable for various machines, with a defined blow out valve for a critical event that would discharge a large volume at a pre determined pressure based lightly on my spring supply. I was hopeing to find a tester or diy apparatus to test them

My goals were a relief valve or several of them that could be adjustable for various machines, with a defined blow out valve for a critical event that would discharge a large volume at a pre determined pressure based lightly on my spring supply. I was hopeing to find a tester or diy apparatus to test them

Here is another online calculator that is pretty good to get you in the ballpark.

https://www.acxesspring.com/free-spring-calculator-download.html

I used it to back calculate force & deflection for miniature valve springs & it correlated well with commercial ones. Its a lot easier to enter a few parameters based on your existing springs & let it tell you its full capability (and limits). Unless, like I mentioned, you already have a known force in mind in which case just apply it to your collection & see if that deflection amount works. I didn't mean to infer you had to make up a 5 pound weight. You can just put the spring on a scale, zero out the tare & push on it until X pounds shows up, whatever you need. Its just that this is clumsy to measure deflection while compressed & doesn't work well with tension springs. Good luck. Don't shoot yer eye out

https://www.acxesspring.com/free-spring-calculator-download.html

I used it to back calculate force & deflection for miniature valve springs & it correlated well with commercial ones. Its a lot easier to enter a few parameters based on your existing springs & let it tell you its full capability (and limits). Unless, like I mentioned, you already have a known force in mind in which case just apply it to your collection & see if that deflection amount works. I didn't mean to infer you had to make up a 5 pound weight. You can just put the spring on a scale, zero out the tare & push on it until X pounds shows up, whatever you need. Its just that this is clumsy to measure deflection while compressed & doesn't work well with tension springs. Good luck. Don't shoot yer eye out